Abstract

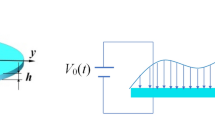

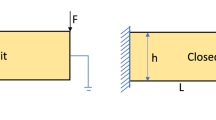

This work presents the development of a two-way coupled flexoelectric plate theory starting from a 3D gradient electromechanical theory. The gradient electromechanical theory considers three mechanical length scale parameters and two electric length scale parameters to account for both mechanical and electrical size effects. Variational formulation is used to derive the plate governing equations and boundary conditions considering Kirchhoff’s assumptions. A computationally efficient \(C^2\) continuous non-conforming finite element is developed to solve the resulting plate equations. To assess the accuracy of the non-conforming finite element framework, the results are compared with Navier-type analytical solution for a simply supported flexoelectric plate. The finite element framework is also validated with experimental results in the existing literature for a passive micro-plate. The results show excellent agreement with both analytical and experimental results. Furthermore, computational efficiency of the non-conforming element is compared with the standard conforming element, which contains greater degrees of freedom and continuity across all elemental edges. It was observed that the non-conforming element is almost twice as fast as the conforming element without a significant loss of accuracy. The 2D finite element formulation is subsequently used to analyze the size-dependent response of flexoelectric composite plates operating in both sensor and actuator modes. Various parametric studies are performed to analyze the effect of boundary conditions, length scale parameters, size of the plate, flexoelectric layer thickness ratio, etc., on the response of flexoelectric plate-type sensors and actuators. It is found that the effective electromechanical coupling increases in a flexoelectric plate at microscale (due to the size effects), and it is higher than standard piezoelectric materials for plate thickness \(h \le 8\,{{\upmu }}\)m.

Similar content being viewed by others

Notes

All the simulations are performed using MATLAB 2019 on a Windows 10 pro desktop computed with 8 core processor having base frequency of 3.70 GHz and 48 GB RAM.

References

Wang, B., Gu, Y., Zhang, S., Chen, L.-Q.: Flexoelectricity in solids: progress, challenges, and perspectives. Prog. Mater. Sci. 106, 100570 (2019)

Deng, Q., Liu, L., Sharma, P.: A continuum theory of flexoelectricity. In: Flexoelectricity in Solids: From Theory to Applications, pp. 111–167. World Scientific (2017)

Majdoub, M., Sharma, P., Cagin, T.: Enhanced size-dependent piezoelectricity and elasticity in nanostructures due to the flexoelectric effect. Phys. Rev. B 77(12), 125424 (2008)

Gregg, J.M.: Stressing ferroelectrics. Science 336(6077), 41–42 (2012)

Yan, Z., Jiang, L.: Flexoelectric effect on the electroelastic responses of bending piezoelectric nanobeams. J. Appl. Phys. 113(19), 194102 (2013)

Zhuang, X., Nguyen, B.H., Nanthakumar, S.S., Tran, T.Q., Alajlan, N., Rabczuk, T.: Computational modeling of flexoelectricity—a review. Energies 13(6), 1326 (2020)

Deng, B., Li, H., Tzou, H.: Optimal positions for multiple flexoelectric actuations on beams. In: ASME International Mechanical Engineering Congress and Exposition, vol. 57564, p. V013T16A008. American Society of Mechanical Engineers (2015)

Zhang, X., Yu, W., Fu, J., Tzou, H.: Flexoelectric control of beams with atomic force microscope probe excitation. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 234(13), 2537–2549 (2020)

Hu, S., Li, H., Tzou, H.: Distributed flexoelectric structural sensing: theory and experiment. J. Sound Vib. 348, 126–136 (2015)

Zhang, X., Li, H., Tzou, H.: Vibration control of a cantilever beam by metal-core flexoelectric and piezoelectric fibers. In: ASME 2014 International Mechanical Engineering Congress and Exposition. American Society of Mechanical Engineers Digital Collection (2014)

Merupo, V.I., Guiffard, B., Seveno, R., Tabellout, M., Kassiba, A.: Flexoelectric response in soft polyurethane films and their use for large curvature sensing. J. Appl. Phys. 122(14), 144101 (2017)

Dai, H., Yan, Z., Wang, L.: Nonlinear analysis of flexoelectric energy harvesters under force excitations. Int. J. Mech. Mater. Des. 16(1), 19–33 (2020)

Liu, C., Hu, S., Shen, S.: Effect of flexoelectricity on electrostatic potential in a bent piezoelectric nanowire. Smart Mater. Struct. 21(11), 115024 (2012)

Deng, Q., Kammoun, M., Erturk, A., Sharma, P.: Nanoscale flexoelectric energy harvesting. Int. J. Solids Struct. 51(18), 3218–3225 (2014)

Yang, W., Liang, X., Shen, S.: Electromechanical responses of piezoelectric nanoplates with flexoelectricity. Acta Mechanica 226(9), 3097–3110 (2015)

Wang, K., Wang, B.: An analytical model for nanoscale unimorph piezoelectric energy harvesters with flexoelectric effect. Compos. Struct. 153, 253–261 (2016)

Ren, H., Sun, W.-F.: Characterizing dielectric permittivity of nanoscale dielectric films by electrostatic micro-probe technology: finite element simulations. Sensors 19(24), 5405 (2019)

Sahin, E., Dost, S.: A strain-gradients theory of elastic dielectrics with spatial dispersion. Int. J. Eng. Sci. 26(12), 1231–1245 (1988)

Maranganti, R., Sharma, N., Sharma, P.: Electromechanical coupling in nonpiezoelectric materials due to nanoscale nonlocal size effects: Green’s function solutions and embedded inclusions. Phys. Rev. B 74(1), 014110 (2006)

Hu, S., Shen, S.: Variational principles and governing equations in nano-dielectrics with the flexoelectric effect. Sci. China Phys. Mech. Astron. 53(8), 1497–1504 (2010)

Romeo, M.: Micromorphic continuum model for electromagnetoelastic solids. Z. Angew. Math. Phys. 62(3), 513–527 (2011)

Romeo, M.: Polarization in dielectrics modeled as micromorphic continua. Z. Angew. Math. Phys. 66(3), 1233–1247 (2015)

Abdollahi, A., Domingo, N., Arias, I., Catalan, G.: Converse flexoelectricity yields large piezoresponse force microscopy signals in non-piezoelectric materials. Nat. Commun. 10(1), 1–6 (2019)

Joshan, Y.S., Santapuri, S.: A gradient electromechanical theory for thin dielectric curved beams considering direct and converse flexoelectric effects. Z. Angew. Math. Phys. 73, 178 (2022)

Wang, K., Wang, B.: Non-linear flexoelectricity in energy harvesting. Int. J. Eng. Sci. 116, 88–103 (2017)

Yue, Y., Xu, K., Chen, T.: A micro scale timoshenko beam model for piezoelectricity with flexoelectricity and surface effects. Compos. Struct. 136, 278–286 (2016)

Sharma, S., Kumar, A., Kumar, R., Talha, M., Vaish, R.: Geometry independent direct and converse flexoelectric effects in functionally graded dielectrics: an isogeometric analysis. Mech. Mater. 148, 103456 (2020)

Tian, X., Xu, M., Deng, Q., Sladek, J., Sladek, V., Repka, M., Li, Q.: Size-dependent direct and converse flexoelectricity around a micro-hole. Acta Mech. 231(12), 4851–4865 (2020)

Sharma, S., Kumar, R., Talha, M., Vaish, R.: Strategies to instigate superior electromechanical response in dielectric materials via converse flexoelectricity. Extreme Mech. Lett. 42, 101138 (2021)

Haque, M.F., Snapp, P., Kim, J.M., Wang, M.C., Bae, H.J., Cho, C., Nam, S.: Strongly enhanced electromechanical coupling in atomically thin transition metal dichalcogenides. Mater. Today 47, 69–74 (2021)

Zhang, Z., Yan, Z., Jiang, L.: Flexoelectric effect on the electroelastic responses and vibrational behaviors of a piezoelectric nanoplate. J. Appl. Phys. 116(1), 014307 (2014)

Li, A., Zhou, S., Qi, L.: Size-dependent electromechanical coupling behaviors of circular micro-plate due to flexoelectricity. Appl. Phys. A 122(10), 1–18 (2016)

Ebrahimi, F., Barati, M.R.: Vibration analysis of size-dependent flexoelectric nanoplates incorporating surface and thermal effects. Mech. Adv. Mater. Struct. 25(7), 611–621 (2018)

Qi, L., Huang, S., Fu, G., Li, A., Zhou, S., Jiang, X.: Modeling of the flexoelectric annular microplate based on strain gradient elasticity theory. Mech. Adv. Mater. Struct. 26(23), 1958–1968 (2019)

Chen, L., Pan, S., Fei, Y., Zhang, W., Yang, F.: Theoretical study of micro/nano-scale bistable plate for flexoelectric energy harvesting. Appl. Phys. A 125(4), 1–11 (2019)

Amir, S., BabaAkbar-Zarei, H., Khorasani, M.: Flexoelectric vibration analysis of nanocomposite sandwich plates. Mech. Based Des. Struct. Mach. 48(2), 146–163 (2020)

Abdollahi, A., Peco, C., Millan, D., Arroyo, M., Arias, I.: Computational evaluation of the flexoelectric effect in dielectric solids. J. Appl. Phys. 116(9), 093502 (2014)

Abdollahi, A., Millán, D., Peco, C., Arroyo, M., Arias, I.: Revisiting pyramid compression to quantify flexoelectricity: a three-dimensional simulation study. Phys. Rev. B 91(10), 104103 (2015)

Liu, W., Deng, F., Xie, S., Shen, S., Li, J.: Electromechanical analysis of direct and converse flexoelectric effects under a scanning probe tip. J. Mech. Phys. Solids 142, 104020 (2020)

Yurkov, A., Yudin, P.: Continuum model for converse flexoelectricity in a thin plate. Int. J. Eng. Sci. 182, 103771 (2023)

Sharma, S., Kumar, A., Kumar, R., Talha, M., Vaish, R.: Geometry independent direct and converse flexoelectric effects in functionally graded dielectrics: an isogeometric analysis. Mech. Mater. 148, 103456 (2020)

Akgöz, B., Civalek, Ö.: A microstructure-dependent sinusoidal plate model based on the strain gradient elasticity theory. Acta Mech. 226(7), 2277–2294 (2015)

Nye, J.F., et al.: Physical Properties of Crystals: Their Representation by Tensors and Matrices. Oxford University Press, Oxford (1985)

Lam, D.C., Yang, F., Chong, A., Wang, J., Tong, P.: Experiments and theory in strain gradient elasticity. J. Mech. Phys. Solids 51(8), 1477–1508 (2003)

Qi, L., Zhou, S., Li, A.: Size-dependent bending of an electro-elastic bilayer nanobeam due to flexoelectricity and strain gradient elastic effect. Compos. Struct. 135, 167–175 (2016)

Rupa, N.S., Ray, M.: Analysis of flexoelectric response in nanobeams using nonlocal theory of elasticity. Int. J. Mech. Mater. Des. 13(3), 453–467 (2017)

Qu, Y., Zhang, G., Fan, Y., Jin, F.: A non-classical theory of elastic dielectrics incorporating couple stress and quadrupole effects: part I-reconsideration of curvature-based flexoelectricity theory. Math. Mech. Solids 26, 1647–1659 (2021)

Danesh, H., Javanbakht, M.: Free vibration analysis of nonlocal nanobeams: a comparison of the one-dimensional nonlocal integral timoshenko beam theory with the two-dimensional nonlocal integral elasticity theory. Math. Mech. Solids 27, 557–577 (2021)

Dehkordi, S.F., Beni, Y.T.: Electro-mechanical free vibration of single-walled piezoelectric/flexoelectric nano cones using consistent couple stress theory. Int. J. Mech. Sci. 128, 125–139 (2017)

Ghobadi, A., Beni, Y.T., Golestanian, H.: Size dependent thermo-electro-mechanical nonlinear bending analysis of flexoelectric nano-plate in the presence of magnetic field. Int. J. Mech. Sci. 152, 118–137 (2019)

Lee, C.K.: Theory of laminated piezoelectric plates for the design of distributed sensors/actuators. Part I: governing equations and reciprocal relationships. J. Acoust. Soc. Am. 87(3), 1144–1158 (1990)

Reddy, J.N.: Mechanics of Laminated Composite Plates and Shells: Theory and Analysis. CRC Press (2004)

Carrera, E.: Historical review of zig-zag theories for multilayered plates and shells. Appl. Mech. Rev. 56(3), 287–308 (2003)

Deng, Q., Shen, S.: The flexodynamic effect on nanoscale flexoelectric energy harvesting: a computational approach. Smart Mater. Struct. 27(10), 105001 (2018)

Nguyen, B., Nanthakumar, S., Zhuang, X., Wriggers, P., Jiang, X., Rabczuk, T.: Dynamic flexoelectric effect on piezoelectric nanostructures. Eur. J. Mech. A Solids 71, 404–409 (2018)

Wang, Q., Quek, S.: Flexural vibration analysis of sandwich beam coupled with piezoelectric actuator. Smart Mater. Struct. 9(1), 103 (2000)

Wang, Q.: On buckling of column structures with a pair of piezoelectric layers. Eng. Struct. 24(2), 199–205 (2002)

Joshan, Y.S., Santapuri, S., Grover, N.: Analysis of laminated piezoelectric composite plates using an inverse hyperbolic coupled plate theory. Appl. Math. Model. 82, 359–378 (2020)

Reddy, J.N.: Energy and Variational Methods in Applied Mechanics: With an Introduction to the Finite Element Method. Wiley, New York (1984)

Reddy, J.N.: An Introduction to the Finite Element Method, vol. 1221. McGraw-Hill, New York (2010)

Babu, B., Patel, B.: On the finite element formulation for second-order strain gradient nonlocal beam theories. Mech. Adv. Mater. Struct. 26(15), 1316–1332 (2019)

Deng, F., Deng, Q., Yu, W., Shen, S.: Mixed finite elements for flexoelectric solids. J. Appl. Mech. 84(8), 081004 (2017)

Eliseev, E.A., Morozovska, A.N., Glinchuk, M.D., Blinc, R.: Spontaneous flexoelectric/flexomagnetic effect in nanoferroics. Phys. Rev. B 79(16), 165433 (2009)

Thai, H.-T., Vo, T.P.: A size-dependent functionally graded sinusoidal plate model based on a modified couple stress theory. Compos. Struct. 96, 376–383 (2013)

Meksi, R., Benyoucef, S., Mahmoudi, A., Tounsi, A., Adda Bedia, E.A., Mahmoud, S.: An analytical solution for bending, buckling and vibration responses of FGM sandwich plates. J. Sandwich Struct. Mater. 21(2), 727–757 (2019)

Joshan, Y.S., Santapuri, S., Srinivasa, A.: Finite element modeling and analysis of low symmetry piezoelectric shells for design of shear sensors. Int. J. Mech. Sci. 210, 106726 (2021)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A

Components of constitutive matrices: The components of \(\mathbf{\overline{H}}\), \(\mathbf{\overline{G}}\), \(\mathbf{\overline{D}}\), \(\mathbf{\overline{E}}\), \(\mathbf{\overline{B}}\) and \(\mathbf{\overline{K}}\) matrices defined in equations (51)–(54) are given as follows:

The components of material matrices \(\mathbf{\overline{Q}^c}\), \(\mathbf{\overline{Q}^g}\), \(\varvec{\overline{\epsilon }}\), \(\mathbf{\overline{k}}\), \(\mathbf{\overline{h}}\) and \(\mathbf{\overline{f}}\) defined in Eqs. (51)–(54) are given by:

where \(\overline{Q}_{ij}^c\), \(i,j=1,2,3\) are the components of stiffness matrix and can be obtained in terms of Young’s modulus c and Poison’s ratio v using the plane stress assumptions [42].

where \(\overline{Q}^g_{11}=2(a_1+a_2+a_3+a_4+a_5)\), \(\overline{Q}^g_{14}=2a_1+a_2\), \(\overline{Q}^g_{18}=a_3+\frac{1}{2}a_2\), \(\overline{Q}^g_{22}=2a_1+2a_4\), \(\overline{Q}^g_{25}=\overline{Q}^g_{14}\), \(\overline{Q}^g_{27}=\frac{1}{2}a_2+a_5\), \(\overline{Q}^g_{33}=\overline{Q}^g_{22}\), \(\overline{Q}^g_{36}=2a_1\), \(\overline{Q}^g_{41}=\overline{Q}^g_{14}\), \(\overline{Q}^g_{44}=\overline{Q}^g_{22}\), \(\overline{Q}^g_{48}=\overline{Q}^g_{27}\), \(\overline{Q}^g_{52}=\overline{Q}^g_{25}\), \(\overline{Q}^g_{55}=\overline{Q}^g_{11}\), \(\overline{Q}^g_{57}=\overline{Q}^g_{18}\), \(\overline{Q}^g_{63}=\overline{Q}^g_{36}\), \(\overline{Q}^g_{66}=\overline{Q}^g_{33}\), \(\overline{Q}^g_{72}=\overline{Q}^g_{27}\), \(\overline{Q}^g_{75}=\overline{Q}^g_{57}\), \(\overline{Q}^g_{77}=a_3+2a_4+a_5\), \(\overline{Q}^g_{81}=\overline{Q}^g_{18}\), \(\overline{Q}^g_{84}=\overline{Q}^g_{48}\), \(\overline{Q}^g_{88}=\overline{Q}^g_{77}\) and \(\overline{Q}^g_{99}=2a_4\).

and

Appendix B

The matrices \(\textbf{D}^\textbf{SS}\), \(\textbf{D}^\textbf{SK}\), \(\textbf{D}^\textbf{GG}\), \(\textbf{D}^\textbf{GE}\), \(\textbf{D}^\textbf{EE}\), \(\textbf{D}^\textbf{EG}\), \(\textbf{D}^\textbf{KK}\) and \(\textbf{D}^\textbf{KS}\) defined in Eq. (84) are given by:

The finite element matrices \(\textbf{K}^\textbf{SS}\), \(\textbf{K}^\textbf{SK}\), \(\textbf{K}^\textbf{GG}\), \(\textbf{K}^\textbf{GE}\), \(\textbf{K}^\textbf{EE}\), \(\textbf{K}^\textbf{EG}\), \(\textbf{K}^\textbf{KK}\) and \(\textbf{K}^\textbf{KS}\) defined in Eq. (85) are given by:

Appendix C

Analytical solution for simply supported flexoelectric composite plates: The derived governing equations for the classical flexoelectric plate are solved analytically for simply supported boundary conditions. The governing differential equations (62)–(66) are obtained in the explicit form using Eqs. (58)–(61). The Navier solution is used to express the primary variables in terms of series solution as follows:

where \(p=\pi m /a\) and \(l=\pi n /b\). The coefficients \(U_{mn},\, V_{mn},\, W_{mn},\) \(\Phi _{mn}\) and \(\gamma _{mn}\) are unknowns to be solved using the Navier solution technique.

In addition, transverse load \(q(\alpha _1,\alpha _2)\) is expressed in terms of Fourier series as

where

The series solutions (125)–(130) are substituted into the explicit form of governing equations, resulting in algebraic equations of the form:

where \(\mathbf{U^g}\) is the vector of unknowns to be solved, which is given by

\(\mathbf{F^g}\) is the resultant force matrix, and \(\mathbf{R^g}\) is the \(5 \times 5\) resultant stiffness matrix. Equation (132) is solved to obtain the displacements and electrostatic potential in terms of Navier coefficients. This general formulation is used to analyze the flexoelectric plate, both in actuator and sensor modes.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Joshan, Y.S., Santapuri, S. Finite element modeling and analysis of flexoelectric plates using gradient electromechanical theory. Continuum Mech. Thermodyn. (2023). https://doi.org/10.1007/s00161-023-01252-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00161-023-01252-6