Abstract

The purpose of this research is to establish the necessary and sufficient conditions for food safety and security during pandemic outbreaks, focusing on the case of COVID-19 to ensure resilience of the food supply chain. The study emphasises on the complexity theory of fuzzy set Qualitative Comparative Analysis (fsQCA), to establish a result-driven definition of Industry 5.0 (I5.0) during and post pandemics. The results of this study revealed that a combination of conditions derived from pandemic policy related reforms and I5.0 enablers will assist manufacturers and suppliers in establishing food safety and security during and post the COVID-19 era in a developing economy. Food safety and security being the goal, based on a survey of 140 food companies, this study provides insights to manufacturers and policymakers to enable selective implementation of I5.0 enabling technologies and pandemic policies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Besides directly affecting human lives, natural disasters also have long-term economic ramifications on different industries. In the event of large natural disasters, SC failures are widely seen as an evident shock to production industries (Permani & Xu, 2022). Globalization has posed a growing challenge to food safety and quality assurance (Creydt & Fischer, 2019). The safety and security of the global food SC suffered a major setback in the year 2019–20 which took the world by surprise, as a phenomenon as such wasn’t seen in decades and impacts which neither SCs ever saw, nor they were prepared for. This natural disaster was the coronavirus (COVID-19) pandemic and global food SCs worldwide were hit tremendously both in terms of demand and supply (Hobbs, 2020). Freund et al. (2022), generalized naturally occurring disasters and biologically occurring natural disasters, such as the COVID-19 pandemic under one roof to study the reshaping of global SCs due to such disasters.

During the disruptions from COVID-19 pandemic, food safety was one of the pillars of societal welfare which got affected and still remains to be the same in some regions (Galanakis, 2020). The food SC is considered one of the most critical among all other SCs as there are multiple, extremely sensitive variables, such as health of the workers, hygiene of the manufacturing facilities and the regions of procurement of the raw materials which determine how ‘healthy’ or ‘consumable’ the food item is. Second and third tier suppliers of companies are often unknown (Abeyratne & Monfared, 2016). The already diminishing trust has seen further reduction and negativity during and after the COVID-19 pandemic as people became sceptical about the origin and journey of the food products, considering COVID-19 infested regions and working personnel. There is a consensus among industry observers that COVID-19 will result in firms reassessing production risks and restructuring their SCs, contributing to the retrenchment of cross-border SCs (Liu & Li, 2020). Reports suggest that shutting down of manufacturing plants, changing consumer behaviours and price increases have altered food and beverage supply chains, especially those of meat products (Hawes, 2020). Populations worldwide went into irrational panic buying due to rise in uncertainty of government protocols and spread of misinformation through social media. As a result, firms faced plant closures due to logistics and transportation bottlenecks and labor shortages, resulting in a bullwhip effect in food supply chains (Kar et al., 2022). These effects were supported by a study in the National Library of Medicine found that COVID-19 placed unprecedented stresses especially on the perishable food supply chains (Moosavi et al., 2022). This led to changes in food prices globally (ref). While assessing the early impacts of the COVID-19 pandemic in the food supply chain and farm distress in India, (Vyas et al., 2021) found that key components which got affected were perishable foods (animal products, fruits and vegetables), wholesale and retail markets, food distribution and logistics challenges (supply chain components) as well as concern over food supply and availability. Economies such as Brazil are aiming towards making their SCs sustainable (Ardekani et al., 2023) and large economies such as North America are looking towards shifting labour-intensive industrial activities to nearby countries instead of depending conventionally on one country. Also to provide Western Europe with regular consumables, companies would look forward to increase their dependence on countries such as Turkey and Ukraine. Such rearrangements of SCs and moving dependency to new suppliers require trust which can be achieved through transparency in carrying out business processes (Shih, 2020).

In response to the COVID-19 crisis, existing methods and approaches have to be reconsidered, including the vulnerability of global SCs, so that the industries become future-proof, resilient, sustainable, and human-centered, with the latter three being the three interconnected values at the core of the latest iteration of the industrial revolution, i.e., Industry 5.0 (I5.0). As an extension to Industry 4.0 (I4.0), I5.0 emphasizes research and innovation to drive a sustainable, human-centered, resilient and sustainable manufacturing industry. In I5.0, many technical visionaries see the manufacturing industry getting back to its human roots (Lu, 2021). Technology's influence on SC management is continuously growing, including big data, the internet of things, Industry 4.0, and blockchains (Duan et al., 2019; Wamba & Queiroz, 2020). As part of the construction of I5.0, some discussions have been held about an age of augmentation where humans and machines will work together harmoniously to achieve better efficiency (Bednar & Welch, 2020).

A few researchers have been focusing attention on food distribution, and in particular the production of eggs, meat, and poultry (Bumblauskas et al., 2020). Companies are developing solutions with blockchain, designed for food traceability. Examples include IBM's Food Trust (DeCastro, 2018), SAP's Leonardo blockchain solution (Perez, 2018), and Cargill's Honeysuckle White turkeys (Cargill, 2018). As an example from Wyoming, blockchain solutions like BeefChain (DeCastro, 2018) are being aggressively pursued by the governments of regions, like Wyoming and Colorado (Evans, 2018). Moreover, the benefits of blockchain technology have been demonstrated in global SCs, cross-border trade, and governance (Chang et al., 2020). Tyson Foods, a major meat processor in the United States, which also implements blockchain technology in their food supply chain, had to go for plant closures as they failed to incorporate COVID-19 policy related reforms in manufacturing (Straight, 2020). The World Economic Forum is looking forward to companies and governments, adopt one of its blockchain frameworks to make supply chains resilient post the COVID-19 pandemic. This framework has been piloted in multiple industries, geographies, and use cases – including with partners representing 85% of the world’s cocoa supply chain, 60 transport ministers from across the world, and with 30 + organizations from the United Arab Emirates blockchain ecosystem (World Economic Forum, 2021).

After reviewing a considerable amount of literature, covering blockchain implementation in the food SC, I5.0, COVID-19 and food safety and security, we found out some shortcomings in the existing literature. Although there are many good quality research articles which separately discuss issues and risks related to COVID-19 and enabling factors of I5.0; to the best of our knowledge, no previous study has attempted to interrelate the policy lessons established from COVID-19 and I5.0 enablers to attain food safety and security through a fuzzy set qualitative comparative analysis in good quality management journals. Hence, based on a survey of 290 respondents from 140 food companies, this study utilized fuzzy-set qualitative comparative analysis (fsQCA). We considered that achieving resilience in the SC refers to configurations of both, policy lessons learnt from COVID-19 and implementation of I5.0 enablers in manufacturing (Ragin, 2008a). As a result, instead of assessing each resilient practice's relative contribution, we implemented fsQCA to compare how food safety and security can be achieved by causal conditions, as combinations of different resilient practices from COVID-19 policy related reforms and I5.0 based technological reforms. In fsQCA, rather than analyzing the independent effects of each variable, we examine the interaction between all conditions (Woodside, 2013).

Sigov et al. (2022), Maddikunta et al. (2022) and Xu et al. (2021) has presented a number of definitions derived through a compilation of conditions defining the notion of I5.0 and also discussed its enabling technologies, but so far, these definitions render insufficient to explain the possible ways to achieve food safety and security during the same. This points to the fact that limited inferential models have been developed to determine different combinations of conditions for achieving food safety and security. This sets an aim for us to determine those properties of blockchain technology, which if incorporated in FSCs would contribute in achieving food safety and security during and post the COVID-19 I5.0 era and also the pattern that they would combine with other causal conditions from COVID-19 policy reforms. Finally, the authors argue that the present work will be able to provide a well-grounded definition of I5.0 for food safety and security considering its resilient, sustainable and human-centred character, which have been missing in existing I5.0 literature so far.

The remaining of the article is structured as follows:

-

Section 2 elaborates the background and related studies, followed by Section 3 providing the theoretical background on complexity and configuration theories arrives at the propositions. Sections 4 and 5 provides the research design and research methodology respectively. Section 6 elaborates the analysis of the data. Section 7 explores the findings of the fsQCA followed by Section 8 summarizing the work done so far under discussions, also providing implications and our result-driven definition of I5.0. Section 9 concludes the study.

2 Background and Related Studies

2.1 An Overview of Food Supply Chains

According to a survey conducted in 2016, 94 percent of consumers regard transparency related to how their food is manufactured, grown or produced as important (Astill et al., 2019). Information about the SC within and amongst firms is often siloed due to isolation of information (Han et al., 2021). When information is opaque, trust between parties is diminished, and real information cannot be exchanged (Jia et al., 2020). Moreover, counterfeit and inferior products pose special challenges to finding their source when tracking is difficult (Zhang & Guin, 2019). Consumers can face this problem when sharing information and ensuring product authenticity, as a result, consumers demand a greater degree of clarity on product safety, quality, and sustainability in a complex SC (Behnke & Janssen, 2020). The complexity of intermediaries aside, the cross-border SC of foods is unique in one other regard, the fact that it is of the ‘cold’ type and unlike the SCs of manufactured goods, the perishable nature of foods calls for specialized equipment and transportation. Therefore Chang et al. (2020), mentioned six challenges in the global SC management scenario, some of which directly determine food safety and security. The challenges are traceability of the raw materials/finished goods, digitalization of the SC, cargo integrity and security to ensure isolation from unauthorized personnel, compliance and trust between stakeholders and stakeholder management.

2.2 Impacts of Pandemic on Food Supply Chains

Hobbs (2020) summarized the COVID-19-induced impacts faced by the global food SCs into demand side and supply side shocks considering flexibility to shift from industrial production to retail-focused production as quickly as possible, keeping in mind, future outbreaks. Hobbs (2020) emphasized that the role of workers should be flexible within the supplier’s organization and suppliers should have contingency sources (supplier’s supplier or farms) which are capable of ramping up their production and supply equal capacity raw materials in case of a sudden outbreak of COVID-19 in any of the major farms supplying raw materials.

Matopoulos et al. (2019) observed certain ‘relationship failures’ in relationships among buyers and suppliers in highly competitive markets as relationships get restricted to only transactions and no commitment. In contrast to such situations, collaborative SC relations call for long term bonding among manufacturers and suppliers, which promotes risk-sharing among parties, reduce production costs and increase productivity (Cao & Zhang, 2011), as buyer–supplier relationships can go under tremendous strain during a pandemic-led severe economic downturn (Matopoulos et al., 2019). As a policy-development, currently, both Canada and the United States do not require self-isolation periods for asymptomatic truck drivers transporting food or animals (Hobbs, 2020). For the food industry during and post the COVID-19 pandemic, Rizou et al. (2020) summarized a series of safety measures and assessed the criticality for each step of the food SC from the farms to consumers to ensure food safety.

2.3 Technology Interventions in Industrial Production Through I5.0

Water and steam were used to power manufacturing and transportation in the first industrial revolution, removing many physical limitations. The development of electrical systems contributed to the second industrial revolution. As a result, electric power replaced water and steam as a source of power for production, and machines were the first to substitute for hand tools in manufacturing. In the third industrial revolution, manufacturing was automated and precision was used to increase production capacity, using electronic equipment and information technology (Xu & Duan, 2019). With Industry 4.0, internet of things, big data analysis, artificial intelligence, blockchain technology, edge computing with federated learning, and other modern technological advances are being combined and implemented more and more, resulting in increased automation and production efficiency. It has been proposed that Industry 5.0 will make use of the creativity of human experts in collaboration with machines that are smart, powerful, and accurate (Maddikunta et al., 2022; Sigov et al., 2022). Xu et al. (2021) has summarized the results of a workshop with the technological heads of the European Union, identifying and defining the enabling technologies as drivers of I5.0. The capabilities of smart machines are enhanced by collaboration with humans, making them far more efficient, easier to automate, and more productive. These enabling technologies as compiled and detailed by Xu et al. (2021), Sigov et al. (2022) and Maddikunta et al. (2022) are briefly explained in Table 1.

2.4 Brief Exploration of Blockchain Technology

The reason for emphasizing more on the importance of blockchain technology in this study is its usefulness leading to its recognition over other technological enablers of I5.0, as established by food technology literature (Kamilaris et al., 2019). Distributed ledger technology (DLT) and peer-to-peer network systems are the two essential features of blockchain technology that set it apart from other I5.0 technological advancements (Dubey et al., 2022). Blockchain is a decentralized, transparent, permanent, trusted, immutable, peer-to-peer transaction system in the form of a digital ledger, supported by pre-defined algorithms and distributed consensus mechanism designed to build trust, and researchers have been aiming to improve its consensus mechanisms over time, so that it stands the tests of these industrial revolutions (Mitra, 2022). As a result, digital records can be preserved for a longer period of time, and digital transactions can be verified and validated without the physical interference of stakeholders, building resilience to external threats (Grover et al., 2018). There are multiple models of blockchain, including public, private, permissioned, and permissionless. Using permissioned blockchains protects client privacy (Nordrum, 2017) and satisfies standards of regulation (Yeoh, 2017). As the literature highlights (Aste et al., 2017; Ying et al., 2018), each new record is linked through hashing to the previous entry. Changes to the block result in a change in the hash value, thereby breaking the chain (Aste et al., 2017; Magazzeni et al., 2017). A copy of the ledger is kept on every node to prevent tampering (Nakamoto, 2008). Trade transactions involved in complex processes such as manufacturing or legal contracts using smart contracts can take the form of a transaction on a blockchain (Grover et al., 2019).

2.5 Blockchain Applications in Food Supply Chains

As an enabler of I4.0 and I5.0, blockchain technology has risen in popularity along with a growing research interest over the years in its integration into SC management. Most industries have adopted blockchain, with manufacturing at the 'knowledge' stage and transportation at the 'decision' stage (Grover et al., 2019). Many managers argue that in order to assess the threats due to future pandemic-like disasters, their firms needed deeper visibility of their upstream supply chains, as visibility into tier-one and tier-two suppliers are inadequate given the complexity and geographical coverage of modern value chains (Sultan, 2022). Also, blockchain has shown early promise for increasing transparency, accountability, quality, risk reduction, trust, flexibility and sustainability in SC activities, according to Kshetri (2018) and Wamba and Queiroz (2020). It is also possible to perform traceability using different technologies and in various ways, including origin authentication, adulteration, and substitutions of species (Batta et al., 2021). Providers can, for example, set up a distributed ledger on a blockchain to add information about cultivated crops, pesticides, fertilizers, machinery, and so on, along with information about transactions with individuals. In addition to farm information, producers can add data about farming practices used on the farm, as well as data on crops and animals, making humans and machine interaction more effective as a result of I5.0. This in turn would allow for greater versatility and constant monitoring activities to be taken on by humans and machines alike. Increasing traceability can improve food safety and integrity (Creydt & Fischer, 2019). Through blockchain technology, food manufacturing companies can quickly identify and pinpoint the origins of outbreaks and mitigate food frauds (Levitt, 2016).

Blockchain technology has recently been integrated with the Internet of Things (IoT) for real-time monitoring and tracing of physical data (Pelé et al., 2022; Zhu et al., 2022). Considering the logistics part of very short shelf-life food products, maintaining the cold-chain is particularly important. ZetoChain, for instance, monitors environmental conditions along every stakeholder in the cold chain, using devices connected to the Internet of Things (Zeto, 2018). Köhler and Pizzol (2020) compiled some of the leading blockchain-based food production projects, aimed at bringing transparency in the manufacturing process, such as OpenSC, Provenance and WWF Pilot for fish, TE-FOOD for meat and eggs, IBM Food Trust for daily consumables, especially mangoes and FairChain for coffee and chocolate. Considering the complications of cross-border trade, adapting to changing regulations and environments is especially convenient with blockchain technology in an untrusted environment and hence it is theoretically and practically valuable to build blockchain-based information systems (Pournader et al., 2020).

Hence, as a solution to this crisis, blockchain technology as an information system, when integrated in the food SC, can record information regarding food products at and between every stakeholder of the SC, which allows companies to ensure favourable working environments, identify fraudulent activities, and take actions quickly when there are risks or frauds (Caro et al., 2018; Kumar et al., 2022), especially during and post the COVID-19 pandemic (Sengupta et al., 2021).

3 Theoretical Background

3.1 Complexity and Configuration Theories

A variance-based approach assumes linear relationships among variables. To overcome this, complex phenomena are examined as clusters of interrelated conditions (Woodside, 2017). To address the cause of organic researchers, Byrne (2005) argues that complexity provides a historically strong reference frame. A complex frame consists of cases and their nested systems, as well as interconnected and intersecting complex systems of their own (Ragin, 2000). One of the most potent concepts of complexity theory is trajectory, which describes the actual pattern of change in a system and deals with the description and understanding of change. A key benefit of complexity theory is that it can handle multiple trajectories and a simple analysis cannot explain causal processes in complex systems and hence contingent causes determine the trajectory of complex systems (Byrne, 2005). Traditionally, causation is viewed as a competition between variables to explain outcome variation. Heterogeneity-oriented approaches consider causation as both multiple and conjunctural. Combining causes in a variety of paths to reach the same outcome, the diversity-oriented approach shows different paths revealing different causes (Ragin, 2000). Further emphasizing heterogeneity, Ragin (2000) asserts that in order to understand fuzzy sets, qualitative breakpoints can be recognized and specified on continua and incorporated into fuzzy sets.

3.2 Theoretical Background and Research Propositions

Causation is difficult to prove in most cases as outcomes of interest are often the result of many causes which are interdependent (Kosmidou & Ahuja, 2019, p.6), asymmetry, equifinality and conjunction being the three main features of causal complexity (Schneider & Wagemann, 2012). An effect can only be produced through a combination of causes and no one cause can produce an outcome on its own, thus leading to conjunction (Tóth et al., 2015). According to the principles of causal asymmetry on which configuration theories are based, a condition or a combination of them that determines a result, need not be necessarily the same as conditions which determine the non-appearance of the same results (Fiss, 2011; Ragin, 2008b). With its fuzzy-set approach, the fsQCA tool is able to capture conditions that are unnecessary but sufficient for explaining the outcome and although necessary parts of the solutions but are insufficient portions of the solution paths which can explain the outcomes (Pappas & Woodside, 2021). A solution may contain such conditions or it may lack them, or there may be conditions which are irrelevant or we may not be concerned about them. A situation in which the outcome is irrelevant indicates that it can either be present or absent and does not affect the overall situation. In our scenario, fsQCA does not consider measures of manufacturing reforms as competing variables to explain food safety and security during and post-COVID-19; it rather asseses to what extent different manufacturing reforms from two different spectrums form configurations amongst themselves that results in the same outcome (Rihoux & Ragin, 2009). Therefore, considering multiple conditions contributing to the outcome, we tried finding out how can I5.0 enablers combined with COVID-19 policy reforms enable food safety and security during and post the COVID-19 era.

The constructs which will play the role of conditions in our study are presented in Table 2 along with their operational definition and source(s) of adoption.

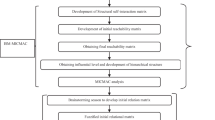

Figure 1 represents the proposed model, illustrating the two main sets of constructs along with their supporting conditions and their influence on the outcome of interest (dependent variable) of this study. The outcome of interest is food safety and security during and post the COVID-19 pandemic in the I5.0 era, the two sets of causal conditions being COVID-19 policy related reforms and I5.0 based technological reforms.

Hence, in the current study, fuzzy configurations for achieving food safety and security might include combinations of pandemic policy-oriented and I5.0 based technological reforms, leading to the following proposition, that:

-

Proposition 1. Configurations that lead to high food safety and security will require the presence of at least one condition each from COVID-19 policy-oriented and I5.0 based technological reforms for manufacturing.

Fiss (2011), indicated that there is a strong association between the core elements and the outcome, and a weaker relationship between peripheral elements. So, researchers can use fsQCA to identify what circumstances must occur for an outcome to occur, that is indispensable, as well as what conditions are more important (or less important) than others. As opposed to examining each characteristic individually, FsQCA helps understand the combination of characteristics. When other conditions exist (e.g., blockchain-induced compliance) blockchain-based supply chain digitalization may be necessary but an insufficient condition for food safety and security to occur during and post the COVID-19 pandemic in the I5.0 era. fsQCA exists mainly for the purpose of dealing with fuzzy-sets, hence for the outcome to occur, it allows us to capture causal conditions that are necessary or sufficient and although necessary parts of the solutions but are insufficient portions of the solution paths which can explain the outcomes. With this, we arrive at our second proposition as:

-

Proposition 2. There would emerge a configuration of conditions which are necessary and a configuration of conditions which are sufficient from a combination of COVID-19 policy related reforms and I5.0-based technological reforms for achieving food safety and security in the I5.0 era.

According to Gonçalves et al. (2016), ‘equifinality’ refers to the possibility that different equally effective conditions can produce the same outcome. The principle of equifinality is inherent in complexity theory and configuration theory, according to which, multiple combinations of determinant conditions will have the same effect (Fiss, 2007; Woodside, 2014). Hence, we arrive at our third proposition as:

-

Proposition 3. No single best configuration of combined COVID-19 policy related reforms and I5.0 based technological reforms would lead to high food safety and security during and posy COVID-19 in the I5.0 era, but there would exist multiple, equally effective configurations of causal factors showing equifinality.

4 Research Design

4.1 Dependent Variables

Building on relevant literature on the principles of complexity theory (Woodside, 2014), this study attempts to establish that COVID-19 policy related reforms and I5.0 based technological reforms, including integration of I5.0 enabler blockchain technology in the SC are important antecedents of food safety and security during and post the COVID-19 era. Therefore, our objective for now would be to obtain the necessary and sufficient conditions for food safety and security during and post the pandemic era in a developing economy, i.e., India. The dependent variable being food safety and security, was determined by instruments adapted from Choe et al. (2009), Han et al. (2015) and Souliotis et al. (2018).

4.2 Independent Variables

Hashemi et al. (2015) emphasized on the technological compatibility and technological developments of a manufacturer’s supplier as one of the key determinants for improving food production quality. Therefore, building upon Hashemi et al. (2015), the food safety and security practices would be measured by an adaptation of instruments of I5.0 enablers from Chang et al. (2020), Xu et al. (2021), Sigov et al. (2022) and Maddikunta et al. (2022) which has 27 items from 5 variables. The instruments of COVID-19 policy related reforms for food production were adapted from Rizou et al. (2020) and Hobbs (2020) having a combined 16 items from 4 variables. The respondents, who were purchase managers or equivalent personnel, were asked to rate the extent to which they would consider certain characteristics of suppliers important, on a 5-point Likert scale ranging from 1: not considering to 5: strongly considering, adhering to the enabling factors of I5.0 and COVID-19 policy reforms to ensure food safety and security practices during and after the COVID-19 pandemic.

5 Research Methodology

5.1 Data Collection

As per the consideration of this study, our contributing stakeholders were the farms at different geographical locations, logistics from farms to processing units, processing units and logistics from processing units to manufacturers. Thus, the questionnaire items for collecting data was based on the aforementioned components of the SC, which were also in-line with Chowdhury et al. (2021). In order to abide by the objective of our study, we considered the same supply chain disrupted areas identified by Chowdhury et al. (2021) which involved management of demand, supply, production, transportation and logistics, relationships among stakeholders and SC-wide impact. The part of the SC under consideration for this study is depicted in Fig. 2, along with the point of collection of data. The sample for this study is elaborated further in Section 5.3.

Firstly, the questionnaire focuses on the impacts and policy lessons faced by typical food SCs during the COVID-19 pandemic according to Rizou et al. (2020) and Hobbs (2020) that is:

-

(i)

Health & Hygiene of workers (CHHW)

-

(ii)

Working environment (CWE)

-

(iii)

Demand side shocks (CDSS)

-

(iv)

Supply side shocks (CSSS)

Secondly, it focuses on I5.0 enabling technologies such as cobots, IoE, digital twins, edge computing with federated learning, big data and AI and blockchain. Blockchain technology and IoT as an enabler of I5.0 has been elaborated and emphasized further for achieving food safety and security, as past studies have spoken intensively and distinctively about the adoption of the same for food safety and security as compared to other enablers of I5.0. Therefore the determinants for the same, as adapted from Hashemi et al. (2015) and Chang et al. (2020) and re-imagined through the vision of Xu et al. (2021), Sigov et al. (2022) and Maddikunta et al. (2022) of Industry 5.0; are:

-

(i)

Industry 5.0 based technological reforms (Use of edge computing with federated learning, big data and AI, cobots, digital twins and blockchain in manufacturing) (ETI)

-

(ii)

Blockchain-based information traceability (BT)

-

(iii)

Blockchain-based protocol-fulfilled cargo integrity and security (BCIS)

-

(iv)

Blockchain-based SC digitalization (BSCD)

-

(v)

Blockchain-induced compliance (BC)

5.2 Survey Instrument

The data collection process of the same using a questionnaire-based survey, employing a 5-point likert scale was carried out on purchase managers (Choi & Hartley, 1996), of different food manufacturers in India as they receive the raw materials from one or more suppliers which are subsequently processed into finished goods. The data was collected across a span of 8 months from February 2022 to September 2022 across all 28 states and 8 union territories of India through online and offline approaches. The responses were recorded in both online and offline modes through soft and hard copies of the same questionnaire by physically approaching the respondents for offline and approaching the respondents through e-mail and their respective social media handles for online modes. A selective sampling approach was followed, since only purchase managers or individuals of similar stature were involved, which was then followed by a snowball sampling approach. The items used for constructing the survey questionnaire along with their factor loadings are presented in Table eight in Appendix A.

5.3 Sample

The questionnaire included a write-up about the importance of this study and a detailed explanation about each of our variables. Next, it included some general questions about the company and the respondent and 46 questions regarding manufacturing practices involving personnel, machinery, materials, technology, methods, environment and hygiene, based on components of the SC shown in Fig. 2. The companies we approached for our survey were food manufacturing brands (which manufactures finished food products and sell them through retail stores), food manufacturing local businesses (food manufactured, stored and sold from the same facility, limited to one branch only in one city), food service companies (food manufactured and sold for immediate consumption without storing) and food retail stores. We identified these companies considering a few criteria: (a) They should have atleast two tiers in their SC including the farm/area of origin before the processed/unprocessed product reaches them as shown in Fig. 2. (b) They should be licensed from the Food Safety and Standards Authority of India (FSSAI). By implementing science-based standards, the FSSAI regulates manufacture, storage, distribution, sale and import of food manufactured by various food companies in India, to ensure consumers get safe and wholesome food. So, a company which processes raw meat and packs them for further sale, whereas a company who uses that packaged meat to produce finished food products for consumption were both amongst our target respondents for the study. A total of 192 food companies were approached for the study, out of which 140 companies participated in the final data pool. Amongst this, 27 were from food manufacturing brands, 59 were from food manufacturing local businesses, 29 were from food service companies and 25 were from the food retail stores. These companies were further categorized into five types regarding the company size in terms of working personnel across all levels, which is shown in Table 3. Our target respondents were purchase managers of these firms or individuals of similar stature. These respondents were further categorized into three types based on their level of education, shown in Table 4.

Next, in order to ensure robustness of the data, we obtained self-feedback on the survey instrument from the respondents to ensure they understood the purpose of the study. Respondents were asked to rate themselves on a scale of 0–10, where 0 depicted that they didn't understand the purpose of the study at all and 10 depicted they completely understood the same. Respondents who rated themselves below 5 were not considered for the study.

The final sample size after the data collection process was 328 responses, out of which 21 were incomplete responses and had to be rejected in the first place. The remaining 307 responses were checked for outliers by finding the Z-scores of the items and outliers detected and removed through conditional formatting. The remaining number of responses from which fair data was analyzed was 290 respondents.

5.4 fsQCA

Ragin (1987) proposed that Qualitative Comparative Analysis (QCA) is an asymmetrical and unconventional method to analyze data by combining the principles of qualitative methods with quantitative data analysis that involves a large number of sample size and is generalizable. By using QCA it is possible to identify combinations (or configurations) of factors/determinants/antecedents that lead to specific outcomes (Ragin, 2008b). Configurations are specific sets of causal variables with synergistic natures that represent an observed outcome or an outcome that is of interest, leading to three main types of QCA, namely: crisp-set (csQCA), multi-value (mvQCA), or fuzzy-set (fsQCA). According to Delery and Doty (1996) and Fiss (2007), an outcome for a given condition, such as user behaviour in information systems research, is considered or can be considered a configuration of interconnected structures, rather than a single isolated entity. According to Park et al. (2020) and Saridakis et al. (2020), QCA can be used for reasoning which is inductive, deductive, and abductive as well as for notably useful theory building, theory elaboration, or testing of theory (Greckhamer et al., 2013; Misangyi et al., 2017), whereas its use and variations has been demonstrated in information systems by Liu et al. (2017), Park and Mithas (2020), and Park et al. (2020).

5.4.1 Advantages of fsQCA Over Traditional Methods

By integrating the principles of fuzzy-logic and fuzzy-sets, a more practical approach can be addressed to, by FsQCA (Ragin, 2000; Rihoux & Ragin, 2009), because variables could have a value between 0 and 1. Compared to traditional analysis methods, fsQCA offers several advantages. By using both qualitative and quantitative assessments, fsQCA identifies sufficient combinations of conditions which are not necessary to attain the outcome (Ragin, 2000; Rihoux & Ragin, 2009), establishing a connection between quantitative and qualitative methodologies (Ragin, 2000). Generally, variance-based methods find out the all-over effect of variables in a model when they examine the competing independent variables, whereas fsQCA analyses the complex and asymmetric relationships amongst the dependent and its causal independent variables. Also, in the behavioural science studies such as IS adoption, control variables which are categorical, such as gender and experience, can also be part of the solution and explain different parts of the sample by combining in different ways. Unlike regression analysis, which considers the best solution, in fsQCA, an outcome can derive from a range of combinations of contributing conditions, and every combination of causal conditions independently contributes to it. Talking about the size and types of data, observations as low as below 50 upto thousands of observations can be analyzed by fsQCA, let that be multimodal, likert-scale or clickstream data. fsQCA divides the sample into multiple subsets. Therefore, unlike variance-based approaches such as structural equation modelling (SEM) and multiple linear regression, which shows the effect of the dominant conditions only, using fsQCA in our study would lead to examining several combinations of causal conditions contributed by COVID-19 policy related reforms and I5.0 based technological reforms. Only a portion of the sample is represented by each configuration, and only some of the potential solutions will contain an outlier. In an analysis which is based on variance-based methods, not all but a portion of the total solutions are likely to explain significant portions of the sample, whereas other solutions would explain smaller portions of the sample because they would be having instances too that are generally considered outliers. Due to its insensitivity to outliers, fsQCA in a way, is more sturdy as compared to methods based on variance (Fiss, 2011; Liu et al., 2017).

The only limitations of fsQCA lies in its biggest positives, where it gives freedom to the researcher to make decisions at different stages of the analysis (e.g., considering the frequency cutoffs for raw consistency and PRI consistency in the fsQCA software). This may introduce subjective bias in the study and therefore it is required of the researcher to justify each decision at every step while proceeding with the analysis.

6 Analysis

6.1 Measurement Reliability and Validity

The 9 variables forming our 2 main constructs were supported by 43 items to increase validity and reliability (Churchill, 1979). The coefficients of Cronbach’s α justified the internal consistency of the variables which were found to be ≥ 0.70 for all variables. Principal component analysis was also used to carry out further assessment of the measurement validities. All items were considered to fit their respective factors well, as the factor loadings of the items were found to be above 0.40. Since the square root of average variance extracted (AVE) for all variables in our study was found to be more than its correlation with every other variable, hence we infer that discriminant validity was supported as well. The factor loadings, mean and standard deviation item-wise and the Cronbach’s alpha and AVE of each variable is depicted in Table eight Appendix A. On being subjected to KMO and Bartlett’s test, the Kaiser–Meyer–Olkin Measure of sampling adequacy was found to be 0.789, any value above 0.5 being considered a good and acceptable value. The statistical significance of Bartlett’s test of sphericity was found to be 0.000 and anything below 0.001 is considered statistically significant. Correlations were also supported (Table nine in Appendix B), as the correlation between all variables were found to be less than 0.8.

6.2 Analysis Through fsQCA

A fuzzy scale (continuous) may be used for outcome and predictor variables using fsQCA rather than a binary scale (discrete). fsQCA features two types of conditions: necessary and sufficient. There may be presence or absence of these configurations, or there may be a "do not care" condition. To conduct fsQCA, the outcome and the independent measures must be identified. Next, we calibrated all measures into fuzzy sets with values ranging from 0 indicating full-set non-membership to 1 indicating full-set membership. The variables were transformed into calibrated set in the fsQCA software, wherein version 3 of the same was used and the step-by-step procedure as suggested by Pappas and Woodside (2021) based on their original article on online purchase behaviour (Pappas et al., 2016), wherein the authors provided a detailed procedure for performing fsQCA was followed throughout. The calibration was done by setting three meaningful thresholds: 0.95 for full set membership, 0.05 for full set non-membership and 0.5 which denoted the cross-over point. To detect which values of the data communicate with the three thresholds, percentiles were used to compute the 95th, 50th, and 5th percentile of our measures and used the values obtained as the three thresholds while calibrating the variables in fsQCA 3 software. The thresholds obtained for the 95th, 50th and 5th percentiles averaged out to be 4, 3 and 2 respectively. It is problematic to assess the conditions which exactly lies on 0.5 (i.e., intermediate-set membership) using fsQCA since the cases that are exactly on 0.5 are excluded (Ragin, 2008b). Under full membership scores of 1, Fiss (2011) recommends that a constant of 0.001 must be added to all the causal variables to overcome this problem. Next, the truth table was generated. Each row of the truth table represents one of the possible combinations of outcome predictors, giving 2 k rows where k represents the number of combinations. After this, the truth table was sorted by frequency by sorting the column ‘number’ (Ragin, 2008b). Since our sample size was 290, we set a frequency threshold at 3 (Fiss, 2011; Ragin, 2008b) and all combinations with frequencies below 3 were removed from further analysis. After sorting the truth table by frequency, it was further sorted by “raw consistency” and a frequency threshold of 0.75 was used (Rihoux & Ragin, 2009). Finally, the PRI consistency scores were also considered, as scores below 0.5 denote considerable inconsistency (Greckhamer et al., 2018). After prioritizing first on the frequency, then on the raw consistency followed by the PRI consistency, the final solution sets were numbered 0 or 1. Choosing 0 or 1 defined whether a combination explains the outcome, as ‘1’ was chosen for all combinations satisfying the above thresholds and ‘0’ otherwise. The allotment of solution scores ‘0’ and ‘1’ is depicted and explained through the truth table in Fig. 3.

On sorting the ‘raw consistency’ column, as it can be seen from Fig. 3, the raw consistency scores are high and gradually decrease with the values being 0.965439, 0.955669, 0.954251, 0.952772, 0.951524, after which there is a natural breakpoint, with the next value being 0.910665. Since all values are well above the consistency threshold of 0.75, therefore we considered the value with a breakpoint as the one having significant inconsistency (Pappas & Woodside, 2021) and hence allotted the solution score ‘0’ whereas all other values were allotted score ‘1’. The "Standard Analysis" approach was then utilised to construct the solution sets that allow for complex, parsimonious, and intermediate solution sets.

7 Findings

7.1 Results from fsQCA

The configurational approach, according to Kosmidou and Ahuja (2019, p. 6), recognizes that cause and effect are difficult to demonstrate because outcomes have the tendency to have more than one interdependent causes. Such interdependence among factors is taken into account by fsQCA as it produces the outcome.

If the outcome cannot occur without certain conditions, in that case such conditions are considered necessary and if the presence or occurrence of a condition always leads to the outcome, in that case such a condition is considered sufficient, although the same outcome could be achieved from other conditions as well (Beynon et al., 2016, p. 5043). The following sections depict the necessary as well as the sufficient conditions for the outcome.

7.1.1 Necessary Conditions

Table 5 presents the analysis of the conditions which are necessary. The solutions yielded that our variables CHHW, CDSS, CSSS, BT, BCIS, BSCD and BC are deemed as necessary conditions for food safety and security during and post COVID-19 I5.0 era as they are having consistency values above 0.9 (Ragin, 2008a).

7.1.2 Sufficient Conditions

Whether a certain combination is a part of the logic-based process of minimization of combinations or not is taken into account differently by the three solution sets, i.e. complex, parsimonious and intermediate. All possible combinations that should be considered in the analysis are considered in the complex solutions. Regardless of whether it is required or not, the parsimonious solutions reduces them to the fewest feasible choices, simplifying the solution. The intermediate solutions do not include combinations that are at odds with theoretical understanding, but they do include a cohesive number of answers to decrease complexity. For interpreting the fsQCA results, the recommended intermediate solutions (Ragin, 2008a) was considered having the final solution sets. In other words, the sufficient solutions are those which are sufficient in themselves to reach the outcome and thus, necessary conditions are not needed for the same. The outcomes of the fsQCA generated three possible combinations of causal conditions that led to food safety and security during and post COVID-19 I5.0 era.

The black circles (●) denote the presence of a condition, crossed-out circles ( ⊗) indicate the absence of one, whereas blank spaces are an indication of a “don't care” situation in which the outcome doesn’t depend on the presence or absence of the causal conditions (Mikalef & Krogstie, 2020). In all cases, demand side shocks, supply side shocks, blockchain-based traceability, blockchain-based SC digitalization and blockchain-induced compliance are present as a core condition. This outcome not only proves that demand side shocks, supply side shocks, blockchain-based traceability, blockchain-based SC digitalization and blockchain-induced compliance are associated with food safety and security during and post COVID-19 I5.0 era, but also that they are necessary conditions for the outcome (Mikalef & Pateli, 2017), reinforcing the results obtained in the previous section of this article. To be specific, solution 1 can be applicable for the food companies which carry out their SC operations where they can achieve food safety and security in an absence of the importance of a working environment, and blockchain-based capabilities of the SC is the only addition they seek in the I5.0 era. Solution 2 also applies for the food companies who carry out their SC operations where they can achieve the outcome in an absence of the importance of a working environment but they do seek other capabilities of I5.0 too along with the implementation of blockchain in their SCs. The third solution presents those companies who believe that the health and hygiene of their workers doesn’t make a difference to them addressing food safety and security whereas the presence of all other conditions are required for the same. These are further discussed in detail in the Discussions section. The solution coverage for food safety and security in COVID-19 I5.0 era is 0.73 and refers to the solution’s explanatory power, i.e., the extent of the outcome, which all the configurations have covered (Rihoux & Ragin, 2009).

As depicted in Table 6, the results obtained show that the same outcome is achieved by different configuration paths of conditions that are equally effective; addressing asymmetry, equifinality, and conjunction, which are the three primary attributes of causal complexity (Schneider & Wagemann, 2012).

In contrast to examining each attribute separately, FsQCA helps understand how they are combined, thus defining equifinality, which states that the same outcome can be achieved from different equally effective configurations of conditions (Gonçalves et al., 2016, p.3).

7.2 Testing for Specific Propositions

After obtaining all the solution sets resulting from fsQCA, we tested for a specific proposition to determine the number of cases in the sample for which the proposition holds true (Pappas, 2018; Pappas et al., 2020). This was achieved by testing our proposition 1 derived earlier in this article, i.e., “Configurations that lead to high food safety and security will require the presence of at least one condition each from COVID-19 policy-oriented and I5.0 based technological reforms for manufacturing”. This was carried out by building a model in fsQCA by computing the required specific configuration and plotting it against the outcome variable, i.e. food safety and security during and post COVID-19 in the I5.0 era. The configuration was computed as explained by the proposition and transformed into a model in fsQCA 3 software using the ‘fuzzyand(x,)’ function. All the independent variables are taken as inputs that we want to test in our proposition. Though all solution paths constitute different scenarios in explaining the outcome, in our case, since solution 2 (Table 6) has the best solution consistency of 0.95104, we will be considering the supporting sufficient conditions of solution 2. This rephrases our proposition 1 as “Configurations where suppliers of manufacturers take care of the health & hygiene of workers, demand side shocks, supply side shocks, implement I5.0 based technological reforms in manufacturing (i.e., cobots, digital twins, edge computing with federated learning, big data and AI) and opt for blockchain-based information traceability, SC digitalization and blockchain-induced compliance will lead to high food safety and security during and post the COVID-19 I5.0 era”. Finally, we plotted the new model using the ‘XY plot’ option in the fsQCA 3 software. The findings (Fig. 4) depicted that the proposition was partially supported. Our outcome variable is represented by X whereas proposition 1 represented by Y.

Figure 4 shows that the extent to which the observations plotted are consistent with X ≤ Y, i.e., X is a subset of Y, is 0.94. The extent to which the observations plotted are having consistency of X ≥ Y, i.e., Y is a subset of X, is 0.72. If either of these two readings depict consistency to be high, the other can be considered as a coverage score (Pappas and Woodside, 2021). Therefore, since the value for X ≤ Y is 0.94 and the value for X ≥ Y is 0.72, the calculations depict that our sample is very much consistent with the fact that X is a subset of Y and the amount of its coverage of Y is 72%, concluding that X accounts for 72% of the sum of the memberships in Y.

7.3 Testing for Predictive Validity

Models from subsample 1In our study, we also tested for predictive validity to determine how well the model predict the dependent variable in additional samples (Woodside, 2014; Wu et al., 2014). A model that is suitable only for a good fit may not be efficient for predicting, hence the importance of determining predictive validity. In simple words, if a sample shows a pattern or a behavior, models developed from a subsample cut out from that main sample would also depict similar behavior, since it is a part of the main sample. This is required to establish the homogeneity of the data and further validity of the findings that if this analysis was carried out roping in more number of respondents from the same population, the results would have been similar. Therefore, we split the total sample in a subsample and a holdout sample. Models developed by performing the same analysis procedure on the subsample were then tested on the holdout sample data. Table 7 shows that the patterns of complex conditions consistently indicate high scores in determining food safety and security during and post COVID-19 in the I5.0 era using the subsample.

Figure 5 presents the findings for the model developed out of the subsample.

8 Discussion

The analysis overall revealed that high food safety and security is achieved by a combination of conditions originating from COVID-19 policy related reforms and I5.0 based technological reforms. To the best of the authors' knowledge, the interplay of the lesson-turned-policies obtained from the COVID-19 pandemic and the enablers of the latest and ongoing industrial revolution I5.0 to achieve food safety and security during the era has not been empirically studied previously on a nation-wide scale having the potential to represent other similar economies. Solution 1 obtained in Section 7.1.2 applies for the food companies which runs their SC operations in an absence of the importance of working environment, and blockchain-based capabilities of the SC is the only addition they seek in the I5.0 era. Blockchain implementation is required by these firms to attain traceability, cargo integrity and security, compliance among stakeholders and overall digitalization of the SC. These might represent those businesses where the human workforce is small and much of the processes are automated. Though workforce is small and not completely absent, therefore health and hygiene of the workers do play a role but the need for a high profile working environment is eliminated. The second solution also represents those companies who operate in the absence of a working environment and the presence or absence of blockchain-based cargo integrity and security is irrelevant to the outcome, whereas other enablers of I5.0 (i.e., cobots, digital twins, IoE, big data & AI, edge computing with federated learning) is required for the outcome. This solution path can be applicable for those firms, who have similar characteristics as the group of firms representing solution 1 but might not involve long distance logistics between stakeholders or might be manufacturing non-perishable foods, eliminating their need for blockchain based cargo integrity and security. The third solution can probably be representative of those firms where much of the processes are automated and all technological enablers of I5.0 are required to achieve food safety and security during and post COVID-19, including complete blockchain implementation among all stakeholders of the supply chain, whereas the presence or absence of the health and hygiene of the workers doesn’t play a role.

Summing it up, this research identifies some key findings. First, it envisions food safety and security during and post COVID-19 in the I5.0 era through the underlying routines described by CHHW, CWE, CDSS, CSSS, ETI, BT, BCIS, BSCD and BC as sufficient conditions to reach the outcome supporting our proposition 1. Moreover, the presence of CDSS, CSSS, BT, BSCD and BC across all solution paths, depict the presence of these core conditions as necessary conditions, whereas CHHW, CWE, ETI and BCIS are sufficient conditions, supporting our proposition 2. Finally, the outcome being food safety and security during and post COVID-19 in the I5.0 era can be achieved through all 3 solution paths where the causal conditions arising from COVID-19 policy related reforms and I5.0 based technological reforms combine in different combinations among themselves, with their raw solution coverages being 38.8%, 35.6% and 58.2% respectively, addressing proposition 3. This raw coverage represents the degree to which a solution accounts for the cases in the data or the proportion of cases in the dataset that are explained by the solution. These findings calls for different paths these reforms can be recognized and implemented, justifying the principle of equifinality, concluding that food manufacturing firms may opt for any of the three solution paths depending on their human workforce, level of automation, length and size of the SC or any other parameter, to attain food safety and security in the I5.0 era.

Although previous authors have defined I5.0 through the perspective of technology, sustainability and bringing in the human factor back into production and manufacturing practices, so far no definitions have been recorded in terms of food safety and security at the age of the pandemic. This has left the definition of I5.0 incomplete, since food safety and security is a matter of utmost importance in the age of pandemics. Therefore, building on existing theories and definitions of I5.0 and summarizing the results of our work, we attempt to define I5.0 from the perspective of food safety and security. The 3 solution paths in our work yielded consistencies of 0.93, 0.95 and 0.94 respectively. The reason why we are taking the consistency into account, is because it is a measure of the degree to which the respective solutions fits the data. It reflects the extent to which the combination of fuzzy sets used to create the solution, accurately represents the empirical distribution of cases across the variables. The consistency score ranges from 0 to 1, where 1 indicates a perfect fit to the data. Therefore considering solution 2, with the highest consistency of 0.95, i.e. a 95% fit to the data as the most optimum, we used its combination of causal conditions to describe I5.0 from the perspective of food safety and security during pandemics. Thus, we define the same as:

I5.0 is the era of manufacturers who achieve food safety and security by focusing on the health and hygiene of their workers and at the same time, have suppliers who are able to cope with demand-side and supply-side shocks, making use of cobots, digital twins, AI and big data and edge computing with federated learning, possessing the ability to digitalize their SCs through IoT-backed blockchain-induced transparency and compliance.

8.1 Theoretical Implications

Industry 5.0 will make use of the creativity of human experts in collaboration with machines that are smart, powerful, and accurate (Maddikunta et al., 2022; Sigov et al., 2022). Yet existing recognitions of I5.0 do not succeed in defining food safety and security, the production of which is also done through industrial processes and involve complex SCs. At the same time, methodological theories applying variance based approaches, fail to explain the different ways in which food safety and security can be achieved by a combination of causal conditions of COVID-19 policy related reforms and I5.0 based technological enablers during and post the COVID-19 era. This study addresses the same through an fsQCA approach. The research questions have been discussed in this section.

Our first research question was to explore how I5.0 enablers combine with reforms derived from lessons learnt from COVID-19 to attain food safety and security (Choe et al., 2009; Han et al., 2015; Souliotis et al., 2018) during this ongoing industrial revolution when pandemic has disrupted food SCs. Addressing this through a large-scale survey, the results indicate that there exist three different combination of causal conditions or solution paths by which COVID-19 policy reforms and I5.0 enabling technologies can combine to achieve food safety and security during and post the COVID-19 pandemic. All three solution paths indicated a mandate of blockchain application in the food supply chain, whereas two out of the three solution paths also called for the integration of other I5.0 enablers. This further enables us to answer our second research question.

Our second research question explores the properties of blockchain technology, which if incorporated in food SCs, including cross-border SCs, would contribute in achieving food safety and security combining with other causal conditions related to COVID-19 policy reforms (Hobbs, 2020; Rizou et al., 2020). The findings revealed that blockchain implementation is an indispensable measure across SCs of all types of food companies in order to bring food safety and security during and post the pandemic era. These causal conditions are further detailed in the next section.

From a methodological standpoint, adding to the theory of complexity and configuration (Byrne, 2005; Ragin, 1987), this study adding to the principle of equifinality (Gonçalves et al., 2016), also explores a number of combinations of conditions that would attain the same outcome, i.e., establishment of food safety and security during and post the COVID-19 I5.0 era. All this is achieved by employing the fsQCA method giving researchers a focused view of the several combinations leading to the outcome.

As supported by Ragin (2000) and Rihoux and Ragin (2009), to establish configurations of conditions or causal variables amongst COVID-19 policy reforms and I5.0 enabling technologies, that are sufficient to attain food safety and security, fsQCA made use of qualitative and quantitative assessments and calculated the degree to which a case from the aforementioned two reforms belonged to a set. This created a bridge between quantitative and qualitative methods and a causality analysis of food safety and security by bringing reforms in the SC during a pandemic-like natural disaster, which further bridges the gap in the literature. Built on data obtained from purchase managers and equivalent personnel in various food companies operating in the era of I5.0, through our analysis results, we arrived at a concrete definition of I5.0 which can be used by researchers in future works on I5.0 as a definition from the perspective of food safety and security during pandemics, thus adding to the literature provided by Xu et al. (2021) and Maddikunta et al. (2022). On a broader perspective, this study addresses and extends the literature of food SCs (Rizou et al., 2020; Sengupta et al., 2021), blockchain as an information system (Dubey et al., 2022; Wamba & Queiroz, 2020), adoption and implementation of blockchain in food SCs of India (Kamble et al., 2019) and Industry 5.0 (Maddikunta et al., 2022; Sigov et al., 2022).

8.2 Managerial Implications

The results of this study yielded that achieving food safety and security during and post COVID-19, can be addressed by manufacturers by making sure that the health and hygiene of workers in the manufacturer’s own plant and supplier’s plant is taken care of whereas the working environment of the plant is not a matter of utmost importance. This supports the claim of previously published studies that rapid surges of infectious cases was hugely caused by the unvaccinated portion of the population (Dutta, 2022). The manufacturer should take note that on events of a future COVID-19 or any pandemic outbreak, leading to shortage of supply of raw materials to the suppliers and panic buying by customers, the situation might lead to supply-side shocks and demand-side shocks respectively, and this should be looked into by manufacturers that their suppliers are capable enough to cope up with such shocks.

Considering the technological component of production, the situation calls for digitalization of the SC by manufacturers through implementation of blockchain technology to make the information from the SCs traceable throughout, right from the farm to retail outlets and be ensured that they travelled through manufacturer-favourable conditions. The situation also calls for providing traceability to the hands of the consumers so that they keep track of what they are consuming. Through the implementation of blockchain-based multi-stakeholder information sharing platforms, the manufacturers would also be able to detect and trace counterfeit or sub-standard materials (Lomotey et al., 2022) which otherwise might have led to a tarnished image of the manufacturer and ensure that the supplier stays compliant to agreed terms and conditions to ensure food safety and security. Carrying out production in the era of I5.0, manufacturers can implement the use of collaborative robots, IoE, digital twins, edge computing with federated learning, big data and AI in the production process to make it more robust.

8.2.1 Policy Implications

Non-supportive policy ecosystem, poor infrastructure and lack of research & development were some of the barriers identified in the logistics part of SCs during the I4.0 era (Sarkar & Shankar, 2021) and the same should be dealt with as 2 out of our 3 solution paths emphasize on blockchain-based cargo integrity and security during I5.0. Governments, food safety and security regulatory agencies and other policy-makers can play a pivotal role in establishing a result-driven setup which strongly supports the findings of this study, further supporting businesses during a pandemic outbreak. A study published in the Lancet revealed that contact tracing and containment policies were just not enough in countries facing more than two waves of the pandemic and had to be followed by stricter measures by the governments including complete lockdowns further disturbing FSCs and making its revival more difficult post pandemic (Lancet, 2023). The Global Preparedness Monitoring Board (GPMB) has highlighted the unprepared self and lack of co-ordination of many developed and developing economies during the pandemic and has concluded the fact that ‘preparedness’ in all aspects, let that be to protect trade or health interests is the key, rather than ‘responses’ to dire consequences of future events of similar pandemics (Kretchmer, 2020). Studies have put forth, vital considerations for local and national governments, civil societies and humanitarian actors at global and national levels with implications for future waves of COVID-19 in low and middle-income countries especially India (Bhatt et al., 2021), as even such a fast-developing economy failed terribly to prevent a deadly second wave of COVID-19 (Biswas, 2021).

Choosing a developing economy, India for this study had some positives. The positive side to this situation is the fact that policymakers, instead of spending capital over the implementation of all enabling factors of I5.0 and planning their rollout all at once, can channel their resources and capital into implementing only those conditions which are deemed sufficient by this study for food safety and security during and post COVID-19 in the I5.0 era. Also, India is a country having a vast difference of terrains and huge cultural differences across state borders. The socio-cultural differences, political influences, economies, fooding habits and working cultures are not constant throughout and differ largely across states. It is pretty evident that people across all these aforementioned territories buy and eat food and there are manufacturers who manufactures in these varied territories and suppliers who supplies to manufacturers across the same. Therefore, conducting this study from data collected across such diversified cultures and geographical terrains, makes this generalizable across a vast geographical domain. The applicability of this study is not only limited to the political boundaries of India, but can be expanded to other neighbouring developing nations too having similar economic, geographical, political and socio-cultural differences. The lessons learnt from COVID-19 should be seriously considered to prepare for and tackle future pandemics (Chung et al., 2021) as even in 2023, the COVID-19 pandemic is sensed to be far from being over (Caruso, 2022; Lancet, 2023), concluding the fact that our research objectives, their analysis and the outcomes of the same would stand the test of time.

9 Conclusions

COVID-19 was a global natural biological disaster which food SCs within and across countries weren’t prepared for. In such an hour of crisis, blockchain technology as an information system can provide a solution to the diminished trust and opacity in SCs to improve the quality of food production. Though we are living in the era of the latest industrial revolution, all of its contributions would be rendered useless if food safety and security is not attained despite all technological triumphs. Therefore, manufacturers should harness the usefulness of cobots, digital twins, IoE, edge computing with federated learning, big data and AI in the food production process and digitalize their SCs by implementing blockchain to bring transparency, trust and make the production process compliant.

Data Availability

The datasets generated during and/or analyzed during this study are available from the corresponding author on reasonable request.

References

Abeyratne, S. A., & Monfared, R. P. (2016). Blockchain ready manufacturing supply chain using distributed ledger. International Journal of Research in Engineering and Technology, 5(9), 1–10.

Ardekani, Z. F., Sobhani, S. M. J., Barbosa, M. W., & de Sousa, P. R. (2023). Transition to a sustainable food supply chain during disruptions: A study on the Brazilian food companies in the Covid-19 era. International Journal of Production Economics, 257, 108782.

Aste, T., Tasca, P., & Di Matteo, T. (2017). Blockchain technologies: The foreseeable impact on society and industry. Computer, 50(9), 18–28.

Astill, J., Dara, R. A., Campbell, M., Farber, J. M., Fraser, E. D., Sharif, S., & Yada, R. Y. (2019). Transparency in food supply chains: A review of enabling technology solutions. Trends in Food Science & Technology, 91, 240–247.

Batta, A., Gandhi, M., Kar, A. K., Loganayagam, N., & Ilavarasan, V. (2021). Diffusion of blockchain in logistics and transportation industry: An analysis through the synthesis of academic and trade literature. Journal of Science and Technology Policy Management, 12(3), 378–398.

Bednar, P. M., & Welch, C. (2020). Socio-technical perspectives on smart working: Creating meaningful and sustainable systems. Information Systems Frontiers, 22(2), 281–298.

Behnke, K., & Janssen, M. F. W. H. A. (2020). Boundary conditions for traceability in food supply chains using blockchain technology. International Journal of Information Management, 52, 101969.

Beynon, M., Jones, P., & Pickernell, D. (2016). Country-level investigation of innovation investment in manufacturing: Paired fsQCA of two models. Journal of Business Research, 69(11), 5401–5407.

Bhatt, M. R., Srivastava, S., Schmidt-Sane, M., & Mehta, L. (2021). Key considerations: India’s deadly second COVID-19 wave: addressing impacts and building preparedness against future waves. https://doi.org/10.19088/SSHAP.2021.031

Biswas, S. (2021, April 19). Covid-19: How India failed to prevent a deadly second wave. BBC News. Retrieved 26 June 2023, from https://www.bbc.com/news/world-asia-india-56771766

Bumblauskas, D., Mann, A., Dugan, B., & Rittmer, J. (2020). A blockchain use case in food distribution: Do you know where your food has been? International Journal of Information Management, 52, 102008.

Byrne, D. (2005). Complexity, configurations and cases. Theory, Culture & Society, 22(5), 95–111.

Cao, M., & Zhang, Q. (2011). Supply chain collaboration: Impact on collaborative advantage and firm performance. Journal of Operations Management, 29(3), 163–180.

Cargill. (2018). Honeysuckle White® expands Thanksgiving traceable turkey program, continuing its commitment to food transparency. Cargill, Incorporated. November Retrieved 25 August, 2022, from https://www.cargill.com/2018/honeysuckle-white-expandsthanksgiving-traceable-turkey-program

Caro, M. P., Ali, M. S., Vecchio, M., & Giaffreda, R. (2018). Blockchain-based traceability in Agri-Food supply chain management: A practical implementation. 2018 IoT Vertical and Topical Summit on Agriculture - Tuscany (IOT Tuscany), 1–4. https://doi.org/10.1109/IOT-TUSCANY.2018.8373021

Caruso, C. (2022, November 17). COVID-19’s Lessons for Future Pandemics. Harvard Medical School News & Research. Retrieved 25 June 2023, from https://hms.harvard.edu/news/covid-19s-lessons-future-pandemics

Chang, Y., Iakovou, E., & Shi, W. (2020). Blockchain in global supply chains and cross border trade: A critical synthesis of the state-of-the-art, challenges and opportunities. International Journal of Production Research, 58(7), 2082–2099.

Choe, Y. C., Park, J., Chung, M., & Moon, J. (2009). Effect of the food traceability system for building trust: Price premium and buying behavior. Information Systems Frontiers, 11(2), 167–179.

Choi, T. Y., & Hartley, J. L. (1996). An exploration of supplier selection practices across the supply chain. Journal of Operations Management, 14(4), 333–343.

Chowdhury, P., Paul, S. K., Kaisar, S., & Moktadir, M. A. (2021). COVID-19 pandemic related supply chain studies: A systematic review. Transportation Research Part E: Logistics and Transportation Review, 148, 102271.

Chung, H. W., Apio, C., Goo, T., Heo, G., Han, K., Kim, T., ... & Park, T. (2021). Effects of government policies on the spread of COVID-19 worldwide. Scientific Reports, 11(1), 20495.

Churchill, G. A., Jr. (1979). A paradigm for developing better measures of marketing constructs. Journal of Marketing Research, 16(1), 64–73.

Creydt, M., & Fischer, M. (2019). Blockchain and more-Algorithm driven food traceability. Food Control, 105, 45–51.

DeCastro, K. (2018). How wyoming ranchers are counting on IBM blockchain for traceability. IBM Think Blog. Retrieved 25 August 2022 https://www.ibm.com/blogs/think/2018/10/how-wyoming-ranchers-are-counting-on-ibm-blockchain-fortraceability/

Delery, J. E., & Doty, D. H. (1996). Modes of theorizing in strategic human resource management: Tests of universalistic, contingency, and configurational performance predictions. The Academy of Management Journal, 39(4), 802–835.

Duan, Y., Edwards, J. S., & Dwivedi, Y. K. (2019). Artificial intelligence for decision making in the era of Big Data–evolution, challenges and research agenda. International Journal of Information Management, 48, 63–71.

Dubey, R., Gupta, M., Mikalef, P., & Akter, S. (2023). Incorporating blockchain technology in information systems research. International Journal of Information Management, 68, 102573. https://doi.org/10.1016/j.ijinfomgt.2022.102573

Dutta, A. (2022). COVID-19 waves: Variant dynamics and control. Scientific Reports, 12(1), 9332.

Evans, B. (2018). Branding, barbed wire and blockchain. Wyoming Business Council. https://www.wyomingnews.com/wyomingbusinessreport/industry_news/advertising_and_marketing/branding-barbed-wire-and-blockchain/article_2985d8d7-a3be-5d94-a238-5bccf0bb47eb.html. Accessed 11 April 2022.

Fiss, P. C. (2007). A set-theoretic approach to organizational configurations. The Academy of Management Review, 32(4), 1180–1198.

Fiss, P. C. (2011). Building better causal theories: A fuzzy set approach to typologies in organization research. Academy of Management Journal, 54(2), 393–420.

Freund, C., Mattoo, A., Mulabdic, A., & Ruta, M. (2022). Natural disasters and the Reshaping of global value chains. IMF Economic Review, 70(3), 590–623.

Galanakis, C. M. (2020). The food systems in the era of the coronavirus (COVID-19) pandemic crisis. Foods, 9(4), 523.

Gonçalves, H. M., Lourenço, T. F., & Silva, G. M. (2016). Green buying behavior and the theory of consumption values: A fuzzy-set approach. Journal of Business Research, 69(4), 1484–1491.

Greckhamer, T., Furnari, S., Fiss, P. C., & Aguilera, R. V. (2018). Studying configurations with qualitative comparative analysis: Best practices in strategy and organization research. Strategic Organization, 16(4), 482–495.

Greckhamer, T., Misangyi, V. F., & Fiss, P. C. (2013). Chapter 3 the two QCas: from a Small-N to a Large-N set theoretic approach. In P. C. Fiss, B. Cambré, & A. Marx (Eds.), Configurational theory and methods in organizational research (Vol. 38, pp. 49–75). Emerald Group Publishing Limited. https://doi.org/10.1108/S0733-558X(2013)0000038007

Grover, P., Kar, A. K., & Janssen, M. (2019). Diffusion of blockchain technology: Insights from academic literature and social media analytics. Journal of Enterprise Information Management, 32(5), 735–757.

Grover, P., Kar, A. K., & Vigneswara Ilavarasan, P. (2018). Blockchain for businesses: a systematic literature review. In S. A. Al-Sharhan, A. C. Simintiras, Y. K. Dwivedi, M. Janssen, M. Mäntymäki, L. Tahat, I. Moughrabi, T. M. Ali, & N. P. Rana (Eds.), Challenges and opportunities in the digital era (pp. 325–336). Springer International Publishing. https://doi.org/10.1007/978-3-030-02131-3_29

Han, L., Hou, H., Bi, Z. M., Yang, J., & Zheng, X. (2021). Functional requirements and supply chain digitalization in industry 4.0. Information Systems Frontiers. https://doi.org/10.1007/s10796-021-10173-1

Han, W., Gu, Y., Wang, W., Zhang, Y., Yin, Y., Wang, J., & Zheng, L. R. (2015). The design of an electronic pedigree system for food safety. Information Systems Frontiers, 17(2), 275–287.

Hashemi, S. H., Karimi, A., & Tavana, M. (2015). An integrated green supplier selection approach with analytic network process and improved Grey relational analysis. International Journal of Production Economics, 159, 178–191.

Hawes, C. (2020, April 23). Food supply chain in peril as plants close amid COVID-19 pandemic. Freight Waves. Retrieved 26 June 2023, from https://www.freightwaves.com/news/food-supply-chain-in-peril-as-plants-close-amid-covid-19-pandemic