Abstract

Significant co-conditioning of aluminum-based sludge using alternative conditioner (natural biopolymer-magnetite/H2O2) as a Fenton conditioner for improving the sludge dewaterability is investigated in the current study. Firstly, natural biopolymer/magnetite (NBP-M) were prepared in various ratios and the samples labeled as (NBP-M-(1:1); NBP-M-(1:3) and NBP-M-(2:1). Focuses were placed on factors influencing such novel Fenton conditioner. Capillary suction time (CST) was utilized to assess sludge dewaterability. Experiments have exhibited that significant development of alum sludge dewaterability could be attained at minimum reaction time and using low concentrations of the applied catalyst, i.e. natural biopolymer/magnetite and H2O2. It was found that sludge conditioning and dewaterability became better with increasing both reagents concentrations. A Box–Behnken experimental design based on the response surface methodology was investigated to explore the optimum of the influencing variables, i.e. catalyst (NBP-M) concentration, H2O2 loading and pH. The optimized values for NBP-M, H2O2, and pH are 46 and 380 mg/L, respectively at pH 3.0, at which the CST reduction efficiency of 58 ± 3% can be attained, this approved with that predicted by an established polynomial model in the current investigation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Inescapable waste is produced through the process of drinking water processing. Potable water quality is cardinal and a sign of modern societies. Thus, the utmost priority for attaining such clean water is to undergo to various unit operations in the drinking water treatment plants (Ashour et al. 2014; Thabet et al. 2020; Thomas et al. 2016). Coagulation, filtration along with sedimentation is the main categories required in the drinking water treatment plant where coagulant aids are used. Such technology is categorized to be an expensive process since the costive chemicals used which compromised of metals, i.e. aluminum and iron in order to precipitate soluble substances in water (Zhao and Yang 2010; Tetteh and Rathilal 2019; Tony 2021). The resultant by-product residual is sludge according to using aluminum sulfate as a primary coagulant, which is referred as “alum sludge”. Such waste is essentially required to be dewatered prior to its final discharge in order to thickening the sludge (Carty et al. 2002; Ashour and Tony 2017; Zhao and Bache 2002a, b).

Although in some places it should discharge alum sludge in economic and efficient way (Thabet et al. 2021; Tony et al. 2016a, b; Zhao et al. 2013; Turner et al. 2019), in other places such as Egypt it disposed directly to the nearby drains which further reach to water sources, such as lakes and rivers (Tony and Tayeb 2016; Tony 2020a, b). A technical solution for such by-product alum sludge waste is to undergo for dewatering technique to minimize its amounts. Alum sludge is a two-phase blend of solids and 99% water, thus it is difficult-to-dewater (Zhao et al. 2021; Vasudevan 2019). Hence, it is subjected for management techniques (Mazari et al. 2018). Alum sludge management train is compromising of successive steps which is so-called thickening, stabilization, conditioning for ease to dewater techniques and the final step is to dispose sludge or introduce it for further reuses (Renou-Wilson et al. 2019; Zhao et al. 2008). Conditioning is exposed for the objective of enhancing alum sludge dewaterability process. Chemical or physical conditioning may be applied (Ren et al. 2020; Tony 2019). Polyelectrolytes, lime, flocculants, acid and ferric chloride are considered as chemical aids conditioners. Mechanical dewatering in press filter, centrifuges or dryers could be applied prior to final sludge disposal (Yin et al. 2004). To satisfy stringent rules and restrictions, sludge conditioning for dewatering techniques is gaining researcher’s attention. Thus, extensive research has been explored to meet such goal (Tony et al. 2008; Zhou et al. 2014). Chemical conditioners still more noticeable effect and posses the advantage of energy-saving that resulting in the addition of flocculating material specially the use of polyelectrolytes (Zhou et al. 2014; Tony 2020a, b). For example, Polyelectrolyte revealed a significant effect on alum sludge conditioning, but its toxicity to the environment is still a concern (Guo et al. 2018). Also, freezing/thawing, thermal hydrolysis or sonication combination (Zhou et al. 2020a, b) are introduced as a conditioner, however those are uneconomic techniques due to the high-energy consumption. Chemical conditioners such as lime, gypsum and oxidation are also previously applied (Ren et al. 2020), but the extensive use of extra reagents as non-benignity chemicals is still causing a severe damage to the environment. Among the conditioners that is leading to a superior suggestion is advanced oxidation conditioning due to its gentleness to the biosphere (Mustranta and Viikari 1993). Hence exploring and taking into account the consideration of lessening the use of chemicals but with a superior treatment is target of the researchers (Wei et al. 2018). Among the used conditioners, advanced oxidation processes (AOPs) specially Fenton-Like reaction is a superior suggestive dewatering method (Tony et al. 2008). But, the chemicals use is a concern that leading the scientists to explore of turning waste materials into a value added material.

However, it is noteworthy to mention that searching for alternative conditioners is attaining researchers’ interest due to the toxic effects of Polyelectrolytes. Recently, advanced oxidation process (AOPs) have been applied as a promising technique in alum sludge conditioning especially the application of Fenton’s reagent which is compromising of Fe2+/3+/H2O2 as a non-polymer (Tony et al. 2009a, b, c). Few investigators (Tony et al. 2008; Zhao et al. 2009) in the last two decades are dealing with Fenton oxidation as a superior conditioning system in comparison to other chemical conditioners. However, although polymers used in conditioning showed toxicity even in very low quantities, its effect is so effective in dewatering of such sludge. Therefore, searching for environmentally benign polymers is crucial (Rebosura et al. 2020). Not only the environmental features are attitudes behind searching for polymer substitutes, but also the economic potential.

Chitosan biopolymer is signified as a non-toxic natural material which posses a high mechanical strength. To add up, it showed successful ability to chemical modification. Chitosan polymer is applied so far in the field of wastewater treatment. However, it is not applied widely in alum sludge conditioning specially in augmentation with iron nanoparticles as a source of Fenton’s reaction. Herein, this study is introducing the use of energy benign materials, magnetite nanoparticles and chitosan polymer as a composite material to condition the sludge to enhance its dewaterability in a green sustainable regard. The composite is prepared in different compromises and the system parameters, i.e. pH, catalyst dose, H2O2 and temperature are explored. Also, the novel system is assessed through comparing with the traditional conditioners.

Experimental section

Materials

Alum sludge

Alum sludge that is so-called, aluminium-based waterworks sludge residue, was collected from Shebin El-Kom City, Menoufia governorate, Egypt. In the Southern Shebin El-Kom City signified as the largest Waterworks plant. In such plant the raw water enters the plant through pumping from the River Nile reservoir. The plant serves the western side of the city which its daily capacity is 40,000 m3 of potable water. Aluminium sulphate is applied in the plant as a coagulating agent for flocculating and coagulating water and thus the resultant from such step is a massive amount of corresponding aluminium-based sludge. For our study, the fresh aluminium-based sludge “alum sludge” was directly collected from the underflow channel of the sedimentation basin. All the collected sludge samples are subjected for transferring to laboratory in an acid-washed plastic tanks for the object of analysis according to the standard methods. Properties of the alum sludge are listed in Table 1.

Natural biopolymer/magnetite

Natural biopolymer that is called chitosan augmented with magnetite nanoparticles composite (NBP-M) were synthesized through simple co-precipitation technique followed by hydrothermal treatment. Firstly, chitosan is dissolved in acetic acid solution as one wt% of the biopolymer in drops of the acid. Then it is dissolved through magnetic stirring in distilled water (50 mL, 15 min). In parallel, FeSO4⋅7H2O and FeCl3 in (1:2) molar ratio is dissolved also in distilled water (each in 50 mL). Subsequently, the 3 solutions were mixed together to attain a mixture of (2:1) from chitosan: magnetite in which sodium hydroxide solution is added gradually to reach to pH to 10. Afterwards, the mixture is exposed for heating (45 min, 90 °C). The resultant precipitate is collected and washed with distilled water to maintain pH neutral. Then, the precipitate is subjected for oven drying (70 °C) and the resultant sample is labelled as NBP-M-(2:1). To add up, to prepare various weight proportions of the composite, different mass ratios of precursors were explored and the samples labelled as NBP-M-(1:1) and NBP-M-(1:3).

Methodology and analytical determination

Firstly, 250 mL of alum sludge samples were carefully transferred to a number of 500 mL of breakers. Thereafter, their pHs were then adjusted, if needed, to the desired values by adding the diluted sulphuric acid or sodium hydroxide solutions into the alum sludge. Diluted sulfuric acid (1:9) and sodium hydroxide (1 M) is used for pH adjustment of the sludge samples (AD1030, Adwa instrument, Hungary). Then, the catalyst, NBP-M is added as the source of Fenton’s catalyst and the Fenton reaction is then initiated by the addition of commercial hydrogen peroxide (30% by wt.). The combination of NBP-M/H2O2 is signified as the oxidizing Fenton’s system. Subsequently, NBP-M (in the range of 20–100 mg/L) and H2O2 (in the range of 100–800 mg/L) were added at the essential doses into the solution as a source of Fenton’s reagent and subjected to a magnetic stirring to ensure mixing and dispersion. Following Fenton reagent addition the beaker containing the sludge and reagents is subjected to a jar test apparatus for 30 s of rapid mixing followed by a slow mixing to stimulate reaction and flocculation during the reaction time. Figure 1 shows graphical illustration of the experimental setup.

Sludge dewaterability after conditioning was assessed by measuring capillary suction time (CST). CST was measured using a CST apparatus (Trition-WPRL, Type 304 M CST). The CST reduction efficiency (%) is calculated by Eq. (1).

where CSTo and CST are, the capillary suction time of the alum sludge before and after adding conditioners, respectively.

X-ray diffraction (XRD) pattern using a Bruker–Nonius Kappa CCD diffractometer equipped with CuKα radiation (λ = 1.5406 Å) was applied to define the XRD of the prepared samples. Furthermore, transmission electron microscope (TEM) analysis has been done (type Tecnai G20, FEI) to investigate the composite morphology. Additionally, the particle size distribution was measured by IMAGEJ 1.48 V program by analysing digital TEM images. Moreover, the morphologies of the raw sludge samples and the corresponding conditioned sludge were investigated and imaged by field-emission scanning electron microscope (SEM) (FE-SEM, Quanta FEG 250).

Box–Behnken design

A Box–Behnken experimental design was selected to investigate the combined effects of the three independent parameters, i.e. pH value, H2O2 dosing and NBP-M-(2:1) dosing as X1, X2 and X3, respectively, during the modified Fenton reagent conditioning. The range of the experimental variables investigated was selected according to preliminary tests and those ranges and levels are arranged in Table 2. 15-runs of experiments were designed according to the Box–Behnken factorial design is required for a complete set of experiments (See Table 3). Initially, the first step in the RSM is to reveal an appropriate approximation for the true functional relationship between the CST reduction response (X, %) and the set of the independent parameters. An empirical second-order polynomial model approximation for the 3-parameters is according to the following Eq. (2).

where X is the predicted response (CST reduction efficiency, (%); \({\beta }_{{\text{o}}}\), \({\beta }_{ii}\) and \({\beta }_{ij}\) (i = 1, 2, 3 and j = 1, 2, 3) are the model regression coefficients; Xi and Xj (i = 1, 2, 3 and j = 1, 2, 3) are the coded independent parameters as shown in Table 2. The coefficient parameters are estimated by multiple linear regression analysis using the software of Statistical Analysis System (SAS 1990; Ashour and Tony 2020).

Results and discussions

Structural and morphological characterization of the prepared conditioners:

XRD analysis

Figure 2 displays the XRD pattern for the synthesized composite material, chitosan as a natural biopolymer (NBP) augmented with magnetite (M) nanoparticles. Figure 2a displays the XRD pattern of the NBP-M-(1:1), (b) NBP-M-(3:1) and (c) NBP-M-(2:1). In all samples the diffraction peaks of the crystalline nature of magnetite nanoparticles that is signified with the corresponding of 2θ (30.05, 35.49, 43.22, 53.63, 57.06, 62.48 and 74.24°) that related to the planes of (111), (220), (311), (400), (422), (511), (440), (533), respectively are defined that representing the JCPDS No. 89-4319 of magnetite. Also, sharp peak broadening is an indication to the small size of nanoparticles. Moreover, the amorphous nature of chitosan is appeared in the three samples.

Furthermore, in order to estimate the crystalline size (D) of the prepared substance powder, the value of the full width at half maximum (FWHM) for the obtained diffraction peaks was applied according to the Debye Scherrer equation (\(Dp=0.94\lambda /\beta cos\theta\)), where: \(\lambda\) is the X-ray wavelength, β is the full width at half maximum intensity of the peak and θ is representing the Bragg diffraction angle. The calculated particle size using Debye Scherrer equation for all the three samples NBP-M-(1:1), NBP-M-(3:1) and NBP-M-(2:1) are as 21, 26 and 35, respectively. This confirms that all samples are in nano-size between 21 and 35 nm.

TEM morphology and particle size

Figure 3 displays the TEM micrograph of chitosan/magnetite composite nanoparticles. Analysis of the results of the TEM images postulated information on the size and morphology of the nanoparticles. It can be revealed from Fig. 3 that the magnetite nanoparticles had a spherical shape with weak agglomeration as seen in all composite materials in Fig. 3a, b and c. However, the presence of chitosan appears as the random shapes and its amount is associated with the weight percent of its addition. Figure 3a represents the composite with a weight percent of chitosan: magnetite of (1:1) and the average particle size is about 20.26 nm as measured by IMAGEJ software. In Fig. 3b represents the TEM micrographs of chitosan: magnetite of (1:3) that means the presence of magnetite is in excess that samples posses a median particle size of 14.72 nm. In such TEM micrographs the spherical particles of the magnetite nanoparticles is in excess (Fig. 3b). As can be seen the average diameter of the composite of chitosan: magnetite (2:1) in Fig. 3c is about 22.87 nm and the presence of excess chitosan is appears as more amorphous non-uniform shapes that are dense in the micrograph more than the spherical nanoparticles of magnetite. Such TEM images revealed a uniformly dispersed magnetite nanoparticles with chitosan biopolymer.

Alum sludge conditioning using modified polymeric Fenton system

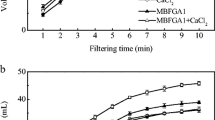

Effect of conditioning reaction time

The effects of modified Fenton reaction time on aluminium-based sludge conditioning were examined at the reagent’s concentrations of 40 and 400 mg/L for composite and H2O2, respectively. The pH of the sludge was kept on its original without any adjustment in one set of experiments and in another set of experiments it is kept at 3.0, while the incubation time of the reaction was varied. The data displayed in Fig. 4 explored the pronounced effect of the presence of Fenton’s reagent combination estimated via CST reduction capability. This was more obvious in the initial period of reaction time especially for the sludge adjusted at pH 3.0. However, quite similar results are attained with prolonged reaction time. However, for the sludge that is kept at its original pH without any adjustment almost similar CST reduction is recorded through the various reaction time, it is notable that 3 min of conditioning time is quite corresponding to higher CST reduction 49%. The maximum CST reduction rate (%) was attained at the first 1 min, which is recorded 53% (at pH 3.0). This optimum reaction time of 1 min is in agreement with the previous finding of Tony et al. (2008) who treated alum sludge using classical Fenton’s reaction who recorded 1 min of reaction time that is enough for conditioning. Also, Zhao et al. (2009) found 1 min is enough for alum sludge conditioning using various Fenton-based systems. Moreover, the results is close to the data in somewhat by Zhang et al. (2005) who found the first 10 min of reaction time is satisfied for conditioning. However, such result is not in agreement with the stated previously in the literature in conditioning activated sludges that reported the time essential for conditioning is 1–2 h (Mustranta and Viikari 1993). This disagreement in the reaction time required for conditioning between the alum sludge and activated sludge may be associated with the nature of the two sludges that differs. According to Zhao et al. (2009), recommended that comparing the source of activated sludge that derived from the biological wastewater treatment to alum sludge, more organics are retained in activated sludge. Thus, less organics present in alum sludge and hence shorter time is required for conditioning through the polymeric/magnetite composite-based Fenton reaction.

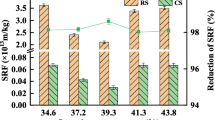

Comparison between various Fenton conditioners

For the object of comparison, the values of the CST reduction efficiency (%) were compared at the optimal dose of the different conditioners namely NBP-M-(1:1), NBP-M-(1:3) and NBP-M-(2:1) augmented with H2O2 at pH 3.0 to initiate the Fenton’s reaction. As shown in Fig. 5 the CST reduction for the combination of NBP-M-(2:1)/H2O2 showed a higher behaviour of dewatering efficiency that gave 52% CST reduction, followed by the NBP-M-(1:1) /H2O2, system (47%) and then the NBP-M-(1:3)/H2O2 (43%). Such result indicates that Fenton’s reagent cannot achieve the same level of CST reduction due to the various natures of catalyst present in the Fenton system. The catalyst is comprised of different combinations of weight percentages of chitosan biopolymeric material and magnetite, which gives a various nature of such materials. The reason may be attributed to the different mechanisms of the chitosan and magnetite nanoparticles during sludge conditioning (Tian et al. 2022). Overall, Fenton’s reaction improves the sludge dewaterability through the active hydroxyl radicals (∙OH) species. Such radicals may attack the sludge’ cells of their organic particles and thus leading to an enrichment in the hydrophobicity and the release of interstitial water that might be trapped inside the organic molecules of such alum sludge (Yang et al. 2006; Tony et al. 2016a, b; Zhao 2004). Moreover, magnetite particles produce ferric ions in the aqueous medium take the significant role of flocculating the sludge particles into aggregate. But, the presence of chitosan as a polymer the mechanism of conditioning differs since polymers might assist the purpose of charge neutralization and also inters particle or primary flocs bridging (Bache and Gregory 2007; Majam and Thompson 2006; Tony et al. 2009a; Tony and Lin 2020). The difference between the three samples is associated to the amount of magnetite or chitosan thus affecting the tendency of dewaterability. Notably, such values are remarkable than that of the CST of the raw sludge which confirms the feasibility of such materials in conditioning.

Effect of temperature

The CST reduction results of aluminium-based sludge conditioning with polymeric type Fenton system using 40 mg/L composite (NBP-M-(2:1) dose and H2O2 at a dose of 400 mg/L at pH 3.0 is investigated at various temperatures in the range of 30 to 60 °C. The data displayed in Fig. 6 revealed the trends of temperature increase declines the effectiveness of the sludge dewaterability particularly beyond room temperature (30 °C). A significant improvement of the sludge dewatering efficiency could be acquired since a CST reduction of 51% at the 60 °C compared to 52% of CST reduction at 30 °C. Such hydrothermally treatment of the sludge may be results in some disintegration in extracellular polymeric substances, which further disrupting the complex sludge flocs structure. Thus the temperature increase is unfavourable (Lv 2019; Tony et al. 2009b). Moreover, temperature increase might destroy the sludge cells and thus the formed flocs are destroyed and may be results in a breakdown of the chemical bonds of the sludge particles (Chen 2021; Tony and Lin 2021). This particular phenomenon of temperature effect on the sludge properties was previously described in the studies of Wang et al., (2017).

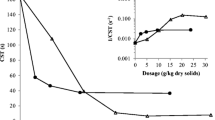

Effect of Fenton’s parameters

Different experiments were conducted using various reagent concentrations and pH to investigate the optimal working conditions of the alum sludge conditioning for maximal dewaterability regime. Initially, as before mentioned in the literature (Tony et al. 2015) Fenton’s parameters plays a significant role in the treatment of Fenton’s reaction. Figure 7a shows that the CST reduction rate influenced with the hydrogen peroxide dosing and the optimal dose was corresponding to 400 mg/L which leads to 56% CST reduction efficiency. Then, a relative smaller reduction on the effectiveness is attained due to the change in hydrogen peroxide to 800 mg/L on the sludge conditioning. Hydrogen peroxide is triggering the hydroxyl (·OH) radicals’ formation that acting as an oxidizing agent. The produced hydroxyl radicals that formed due to the reaction between magnetite and hydrogen peroxide especially at acidic medium plays a significant role in flocs formation. To produce such radicals, the H2O2 amount might be in an optimal presence in the medium and a series of successive reactions occurs according to Eqs. (3–6). This investigation is previously stated in the literature (Tony and Tayeb 2016).

Magnetite and chitosan are a rate-limiting step in this catalytic cycle. From this regard, keeping all other parameters constant the effect of catalyst (composite) dosing is evaluated through altering its amount in the range of 20–100 mg/L. The results displayed in Fig. 7b revealed that increasing the catalyst dose enhancing the dewaterability of the alum sludge and the composite addition should be in an optimal dosing. Hence, for the Fenton’s reaction, further radicals are generated via the chain reactions \({{\text{OH}}}^{-}\) and \({{\text{OH}}}_{2}^{\cdot }\) and the oxygen radicals (Eqs. 7–12). Also, Fe2+/Fe3+ is hydrolysis through the reactions. Moreover, the presence of both reagents, hydrogen peroxide and catalyst, must be in optimal occurrence or may be otherwise hydrogen peroxide acting as ·OH radical scavenger rather than a producer (as seen in Eq. 7 and 13). Furthermore, the presence of chitosan polymer in an optimal dose also controlling the coagulating and flocculating mechanisms (Zhao et al. 2009).

As previously stated in the literature (Tony and Lin 2020), the matrix pH is suggested as a vital parameter that influencing the Fenton system. Since producing hydroxyl radicals is not only depending on the dosing of the reagents of H2O2 and catalyst, but also it controlled by the pH of the medium. Efficient •OH radicals’ generation in high yield represents an increase in the overall reaction yield. Thus, optimal pH plays an important role on the radicals production meanwhile above or below this limit restrains the reactive radicals formation. Claiming that polymeric Fenton system is manipulated by the initial pH of the medium, a set of experiments was conducted in the pH ranged from 3.0 to 8.0 including the original pH (6.6.) of the sludge without adjustment and keeping the reagent doses constant at 400 and 40 mg/L for hydrogen peroxide and catalyst composite, respectively and reaction time of 1 min in order to estimate the influence of pH on Fenton reagents conditioning of alum sludge. The results displayed in Fig. 7c verifies that the presence of the alum sludge at pH 3.0 improves the CST reduction to reach to its maximum value (52%).

The acidic pH environment could be attributed in enhancing the sludge conditioning and dewaterability with pH of 3.0 being the best. This may be associated with the release of metal ions, such as Al and Fe from the sludge to promote the flocculation, as previously investigated by Ren et al. (2020). Furthermore, ζ-potential of the raw alum sludge is recorded at − 12.2 mV. The more negative ζ-Potential, the smaller particle size of the sludge flcos and consequently, the ore turbid is the sludge supernatant. A noble big floc size and stable floc might be generated at a ζ-Potential ranged from − 8.0 to + 3.0 mV (Tony 2020a, b). Thereby, the pH 3.0 is signified as the pH value for alum sludge stabilization. This phenomenon is in agreement with the statement claimed by Zhen et al. (2013) on dewatering of activated sludge using Fenton’s reagent who found acidic pH is favorable for conditioning.

Optimization of Fenton’s reagent operating variables using RSM

To locate the optimum operating variables that affecting the Fenton’s system in alum sludge conditioning regime, a Box–Behnken factorial design was used. The three-level experimental design based on 15 runs (listed in Table 3) are conducted and the results are compared with those predicted values and the data are plotted in Fig. 8. The second-order fitting polynomial equation was then attained from the data fitting as displayed in Eq. (14).

According to the results displayed in Fig. 8, it can be seen that a good agreement of the data between the experimental and the predicted is attained. That verifies the reliability of the suggested model to describe the modified polymeric type Fenton reaction behaviour in alum sludge conditioning.

For additional polynomial model (Eq. 14) assessment, statistical test based on the analysis of variance (ANOVA) that is applied using SAS software was carried out and the statistical implication of the variables regarding the response (X) of the conditioning process was examined by Fisher’s ‘F’ test (F-value is defined as the ratio of MS (mean square) of regression to the mean square of the error) (SAS 1990). The probability value (P-values) is a sign used to check the implication of the model. Generally, the model is acceptable when the probability value (P > F) is minimum that is less than > 0.05 (SAS 1990). The suggestive model is checked for ANOVA analysis and the data displayed in Table 4. From the analysis of variance (ANOVA test) F-value of the model is 4.93 with minimum value of P > F which is corrospoding to 0.04. Additonally, the model is acceptable when the R2 (regression coefecient) is more than 0.80, in the predicted model it is estimated that R2 is 0.95. Such data is a verification of the model significace.

3-D surface and its corresponding 2-D contour illustrations for the CST reduction efficiency that represents the response (X, %) designed by MATLAB (7.11.0.584) software is an informative and visualized representation to facilitate the interacting relation between the operating variables and the corresponding response (X), whereas the third parameters was kept at its zero level (constant value). Figure 9a and b displays the CST reduction as a response under the variable concentrations of H2O2 dosing and the pH value. It is exhibited that suggestive improvement in the CST reduction (%) is attained by hydrogen peroxide concentration increases. But, high hydrogen peroxide doses results in a decline in the CST reduction, which is negatively affected. Hence, an excess of such reagent does not mean a continuous increase in CST reduction of the conditioned sludge. Also, the reduction percentage of CST increased with increasing the pH value up to a certain limit after that it became slower. Similarly, the 3-D surface and 2-D contour plot of the composite dosing and pH value relation is displayed in Fig. 10a and b, respectively. The plot shows that the combination of the composite concentration and pH has a significant improvement on CST reduction. Figure 10 demonstrates that the increase in pH with the increase in the composite dosing improved the efficiency of CST reduction in a certain region; beyond that region the less reduction of CST is attained. Figure 11a and b displays the correlation between the two parameters composite and hydrogen peroxide dosing. The plot verifies that the CST reduction enhanced with both reagents increase till a certain limit, which is a limiting step. Consequently, optimising the composite+ and H2O2 dosing as well as pH value was carried out to attain the highest CST reduction.

Furthermore, Mathematical software (V 5.2., Wolfram research Inc.) was applied to locate the optimum operating variables of the alum sludge conditioning using polymeric Fenton’s regime. The maximum values of the system variables in coded values are displayed as \(\tau\)1 = 0.14, \(\tau\)2 = − 0.19 and \(\tau\)3 = 0.3, whereas the corresponding predicted response is 56%. According to relation between \(\tau\) i and Xi, the natural values of the test variables are shown in Table 5.

For the object of model verification, three additional replicates of experiments using the optimum operation conditions tabulated in Table 5 were carried out. The data of the conducted experiments yielded an average CST reduction efficiency of 58%. Such results clearly demonstrated the efficiency of model to optimise the polymeric Fenton regime.

The microstructural characteristic in the alum sludge

Figure 12 represents the XRD pattern of the alum sludge powder conditioned with the Fenton’s reagent (NBP-M/H2O2). The diffraction peaks at 2θ values of 30.0° (220), 35.3° (311), 43.0° (400), 56.9° (511), and 62.8° (440) are signifying the standard XRD data for the pure cubic spine crystal structure of magnetite (JCPDS No. 89-4319). Also, the XRD pattern well-defined sharp diffraction peaks, which were recognized as the contribution of complex phases including graphite, quartz and calcium aluminum silicate, which indicates that are good crystalline phase. Notably, the diffraction peaks of (002), (011), and (103) represent graphite and the peaks of (014), (002) and (002) of quartz, also, the (104), (004) and (022) signify calcium aluminum silicate. There is no significant shift in the characteristic peaks of the magnetite and that verifies the crystallinity of the magnetite is still retained in the nanocomposite.

Figure 13 displays a SEM image of the raw alum sludge cake that was soft and the conditioned alum sludge cake, which was compact. In the case of the raw alum sludge, SEM image reveals the floc particles, which possess various shape and size, with an intact, smooth surface and non-porous structure (Fig. 13a) (Lin et al. 2019). The SEM image attained for the conditioned sludge exhibits clear differences. In such case the particle size showed a slightly increase (Fig. 13b). Furthermore, the particles surface poses a discontinuous and porous structure. Such description could be due to the effect of the conditioner, Fenton’s reaction, which compromises of chitosan and magnetite that connecting the particles and creating certain pore structure (Zhang et al. 2014). Thus as abovementioned high temperature conditions caused structure destruction because of the effect of the strong oxidation capacity (Zhang et al. 2018). To add up, the porous structure of sludge flocs after conditioning affords channels for water transferring that might leads to extra enhancement in sludge dewaterability (Chen et al. 2019; Chen 2021). It is noteworthy to mention that, no massive change of particle size between the raw and conditioned sludge that signify the conditioning regime might not triggering a complete floc rupture, however, stripped the floc surface by redox reaction (Chen 2021; Tony 2021). That results are inconsistent with that attained from the particle size distribution data.

The results are verified by the particle size analysis. The median change in the particle size was increased from 1.1 µm for the raw sludge to 1.46 µm for the conditioned sludge with maximum particle size increase from 1.94 to 3.216 µm for the raw and conditioned sludge, respectively. This confirms the creation of cation chemical bonds that leading to particles agglomeration and the particle size increased due to the oxidation treatment via chitosan-magnetite-based Fenton system (Zhang et al. 2018).

The scattered results tabulated in Table 6 demonstrate that various limited studies dealt with alum sludge residual from different places water treatment plants (WTPs) in the last two decades. Although polymer conditioning that is applied to enhance sludge dewatering reveals the highest sludge dewatering efficiency based on capillary suction time (CST), specific resistance for filtration (SRF) and dry solids (DS), it is notably to mention that toxicity associated with polymers poses as a problem. Hence, the researchers are dealing with finding alternative conditioners since the cationic polymers categories are hazards to the aquatic organisms and marine systems. Therefore, according to their toxic effect, strict regulations are applied to the save both the environment and marine life to stop their sever damage. Although alum sludge dewatering though AOPs (advanced oxidation process) through Fenton and Fenton-like oxidation is not superior as polyelectrolytes dewatering, it is noteworthy to mention that it is an environmentally friendly option. However, improving such Fenton method is still a research topic. Thus introducing methods to enhance Fenton’s process is a prerequisite. Whereas, the current study showed lower dewaterability efficiency (according to CST reduction of 58%), it is a superior study since it is a dual effect from using an environmentally benign material of natural polymer and magnetite as a source of Fenton’s oxidation. Such technique could be recommended as a green alternative opportunity.

Conclusion

Natural biopolymeric chitosan augmented with magnetite nanoparticles (NBP-M) composite as a base of Fenton reaction showed an enhanced effect on the sludge dewatering performance by decreasing the CST to 58%. Such results were mostly due to the bridging mechanism, which further resulted in the increase in the particle size of the sludge flocs. Thus the result is improving the alum sludge conditioning which further improving the dewaterability and filterability of such sludge. Also, NBP-M/H2O2 demonstrated its potential application in alum sludge conditioning and can be specified as considered as an ideal substitute for organic commercial polymer or traditional conditioners demonstrated its unique superiority in improving the alum sludge dewatering to a reasonable degree in an environmentally benign way for a sustainable waste management. The system parameters were investigated and the optimal operating parameters signified as 40 and 400 for NBP-M and H2O2, respectively, at acidic pH (3.0). However, the temperature increases is unfavourable. All the above data were verified by the comparison of the raw alum sludge microstructure and microtopography after the conditioning.

References

Ashour EA, Tony MA (2017) Equilibrium and kinetic studies on biosorption of iron (II) and iron (III) Ions onto eggshell powder from aqueous solution. Appl Eng 1(3):65–73

Ashour EA, Tony MA (2020) Eco-friendly removal of hexavalent chromium from aqueous solution using natural clay mineral: activation and modification effects. SN Appl Sci 2(12):1–13

Ashour A, Tony MA, Purcell PJ (2014) Use of agriculture-based waste for basic dye sorption from aqueous solution: kinetics and isotherm studies. Am J Chem Eng 2(6):92–98

Bache DH, Gregory R (2007) Flocs in water treatment. IWA Publishing, London

Carty G, O’Leary G, Crowe M (2002) Water treatment manuals: coagulation, flocculation and clarification. Environmental Protection Agency, Wexford, p 85

Chen Y, Chen H, Li J, Xiao L (2019) Rapid and efficient activated sludge treatment by electro-Fenton oxidation. Water Res 152:181–190

Chen K, Liu J, Huang S, Mei M, Chen S, Wang T, Li J (2021) Evaluation of the combined effect of sodium persulfate and thermal hydrolysis on sludge dewatering performance. Environ Sci Pollut Res 28(6):7586–7597

Ghebremichael KA, Hultman B (2004) Alum sludge dewatering using Moringa oleifera as a conditioner. Water Air Soil Pollut 158(1):153–167

Guo J, Chen C, Jiang S, Zhou Y (2018) Feasibility and mechanism of combined conditioning with coagulant and flocculant to enhance sludge dewatering. ACS Sustain Chem Eng 6(8):10758–10765

Lin F, Zhu X, Luo Y, Peiran Yu, Liu M (2019) The microstructural characteristic in the alum sludge: Improvement of activated sludge dewatering properties using green conditioners: chitosan hydrochloride and lysozyme. RSC Adv 9:6936

Lv H, Liu D, Zhang Y, Yuan D, Wang F, Yang J, Wu X, Zhang W, Dai X (2019) Effects of temperature variation on wastewater sludge electro-dewatering. J Clean Prod 214:873–880

Ma W, Zhao YQ, Kearney P (2007) A study of dual polymer conditioning of aluminum-based drinking water treatment residual. J Environ Sci Health, Part A 42(7):961–968

Majam S, Thompson PA (2006) Polyelectrolyte determination in drinking water. Water SA 32(5):705–707

Mazari L, Abdessemed D, Szymczyk A (2018) Evaluating reuse of alum sludge as coagulant for tertiary wastewater treatment. J Environ Eng 144(12):04018119

Mustranta A, Viikari L (1993) Dewatering of activated sludge by an oxidative treatment. Water Sci Technol 28(1):213–221

Pan JR, Huang C, Cherng M, Li K-C, Lin C-F (2003) Correlation between dewatering index and dewatering performance of three mechanical dewatering devices. Adv Environ Res 7(3):599–602

Rebosura M Jr, Salehin S, Pikaar I, Kulandaivelu J, Jiang G, Keller J, Yuan Z (2020) Effects of in-sewer dosing of iron-rich drinking water sludge on wastewater collection and treatment systems. Water Res 171:115396

Ren B, Lyczko N, Zhao Y, Nzihou A (2020) Integrating alum sludge with waste-activated sludge in co-conditioning and dewatering: a case study of a city in south France. Environ Sci Pollut Res 27(13):14863–14871

Renou-Wilson F, Moser G, Fallon D, Farrell CA, Müller C, Wilson D (2019) Rewetting degraded peatlands for climate and biodiversity benefits: Results from two raised bogs. Ecol Eng 127:547–560

Ruhsing Pan J, Huang C, Gang Fu C (2000) Effect of surfactant on alum sludge conditioning and dewaterability. Water Sci Technol 41(8):17–22

SAS (1990) SAS /STAT user’s guide. SAS Institute Inc, Cary, NC

Sun Y, Fan W, Zheng H, Zhang Y, Li F, Chen W (2015) Evaluation of dewatering performance and fractal characteristics of alum sludge. PLoS ONE 10(6):e0130683

Tetteh EK, Rathilal S (2019) Application of organic coagulants in water and wastewater treatment. Organic Polymer. IntechOpen, London

Thabet RH, Tony MA, El Sherbiny SA, Ali IA, Fouad MK (2020) Catalytic oxidation over nanostructured heterogeneous process as an effective tool for environmental remediation. IOP Conf Ser: Mater Sci Eng 975:012004

Thabet RH, Fouad MK, Ali IA, El Sherbiney SA, Tony MA (2021) Magnetite-based nanoparticles as an efficient hybrid heterogeneous adsorption/oxidation process for reactive textile dye removal from wastewater matrix. Int J Environ Anal Chem 103:1–23

Thomas B, Murphy DJ, Murray BG (2016) Encyclopedia of applied plant sciences. Academic Press, Cambridge

Tian G, Li L, Liu Bo, Zhang T, Hua X, Zhang L, Bian Bo (2022) Enhancing the dewaterability of the municipal sludge by flocculant combined with skeleton builder. Environ Technol Innov 25:102166

Tony MA (2020a) Zeolite-based adsorbent from alum sludge residue for textile wastewater treatment. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-020-02646-8

Tony MA (2020b) Central composite design optimization of Bismarck dye oxidation from textile effluent with Fenton’s reagent. Appl Water Sci 10(5):1–9

Tony MA (2021) Nexus approach: ZSM12 derived from industrial waste and organic wax pair for microencapsulated solar energy storage system. Energy Sources Part a: Recovery, Util, Environ Eff. https://doi.org/10.1080/15567036.2021.2001119

Tony MA (2022a) Low-cost adsorbents for environmental pollution control: a concise systematic review from the prospective of principles, mechanism and their applications. J Dispers Sci Technol 43(11):1–23

Tony MA, Lin LS (2020) Performance of acid mine drainage sludge as an innovative catalytic oxidation source for treating vehicle-washing wastewater. J Dispers Sci Technol. https://doi.org/10.1080/01932691.2020.1813592

Tony MA, Lin L-S (2021) Iron coated-sand from acid mine drainage waste for being a catalytic oxidant towards municipal wastewater remediation. Int J Environ Res. https://doi.org/10.1007/s41742-020-00309-7

Tony MA, Lin LS (2022a) Attenuation of organics contamination in polymers processing effluent using iron-based sludge: process optimization and oxidation mechanism. Environ Technol 43(5):1–10

Tony MA, Tayeb AA (2016) Response surface regression model in optimization of alum sludge drying facility: solar-Fenton’s reagent dewatering. Int J Chem Eng Appl 7(5):331

Tony MA, Zhao YQ, Fu JF, Tayeb AM (2008) Conditioning of aluminium-based water treatment sludge with Fenton’s reagent: effectiveness and optimising study to improve dewaterability. Chemosphere 72(4):673–677

Tony MA, Zhao YQ, Purcell PJ, El-Sherbiny MF (2009a) Evaluating the photo-catalytic application of Fenton’s reagent augmented with TiO2 and ZnO for the mineralization of an oil–water emulsion. J Environ Sci Health, Part A A44(5):488–493

Tony MA, Purcell PJ, Zhao YQ, Tayeb AM, El-Sherbiny MF (2009b) Photo-catalytic degradation of an oil-water emulsion using the photo-Fenton treatment process: Effects and statistical optimization. J Environ Sci and Health, Part A 44(2):179–187. https://doi.org/10.1080/10934520802539830

Tony MA, Zhao YQ, Tayeb AM (2009c) Exploitation of Fenton and Fenton-like reagents as alternative conditioners for alum sludge conditioning. J Environ Sci 21(1):101–105

Tony MA, Purcell PJ, Zhao Y, Tayeb AM, El-Sherbiny MF (2015) Kinetic modeling of diesel oil wastewater degradation using photo-fenton process. Environ Eng Manag J 14(1):11–16. https://doi.org/10.30638/eemj.2015.002

Tony MA, Tayeb A, Zhao YQ (2016a) An alternative arrangement for the alum sludge management: minimising waste with low-cost solar techniques. Am J Chem Eng 4(2):30–37

Tony MA, Tayeb AM, Zhao YQ (2016b) An alternative arrangement for the alum sludge management: minimising waste with low-cost solar techniques. Am J Chem Eng 4(2):30–37

Tony MA, Ashour E (2014) Sustainable development: Effects of reusing water treatment plant sludge in brick manufacturing accepted for oral presentation in the 7th international conference for chemical and environmental engineering, Military technical college, May 27–29, Cairo, Egypt

Tony M (2019). Win-win wastewater treatment to sustain world: porous adsorbents from waste waterworks sludge for phenol remediation. Paper presented at the Anaerobic Digestion Conference AD16, The International water Association, IWA

Turner T, Wheeler R, Stone A, Oliver I (2019) Potential alternative reuse pathways for water treatment residuals: remaining barriers and questions—a review. Water Air Soil Pollut 230(9):1–30

Vasudevan G (2019) Performance of Alum Sludge as partial replacement for cement adding superplasticizer. Paper presented at the IOP Conference Series: Materials Science and Engineering

Wang LF, Qian C, Jiang JK, Ye XD, Yu HQ (2017) Response of extracellular polymeric substances to thermal treatment in sludge dewatering process. Environ Pollut 231(Pt 2):1388–1392

Wei H, Gao B, Ren J, Li A, Yang H (2018) Coagulation/flocculation in dewatering of sludge: a review. Water Res 143:608–631

Wu CC, Wu JJ, Huang RY (2003) Floc strength and dewatering efficiency of alum sludge. Adv Environ Res 7(3):617–621

Yang Y, Zhao YQ, Babatunde AO, Wang L, Ren YX, Han Y (2006) Characteristics and mechanisms of phosphate adsorption on dewateredalum sludge. Sep Purif Technol 51(2):193–200

Zhang H, Choi HJ, Huang C (2005) Optimization of Fenton process for the treatment of landfill leachate. J Hazard Mater 125(1–3):166–174

Zhang H, Yang J, YuW LS, Peng L, Shen X, Shi Y, Zhang S, Song J, Ye N, Li Y, Yang C, Liang S (2014) Mechanism of red mud combined with Fenton’s reagent in sewage sludge conditioning. Water, Res 59:239–247

Zhang X, Cai AH, Shenc AJ, Zhang H (2018) Effects of potassium permanganate conditioning on dewatering and rheological behavior of pulping, activated sludge: mechanism and feasibility. RSC Adv 8:41172

Zhao YQ (2004) Settling behaviour of polymer flocculated water-treatment sludge I: analyses of settling curves. Sep Purif Technol 35:71–80

Zhao YQ (2006) Involvement of gypsum (CaSO4· 2H2O) in water treatment sludge dewatering: a potential benefit in disposal and reuse. Sep Sci Technol 41(12):2785–2794

Zhao YQ, Bache DH (2002a) Integrated effects of applied pressure, time, and polymer doses on alum sludge dewatering behaviour. Waste Manag 22:813–819

Zhao YQ, Bache DH (2002b) Integrated effects of applied pressure, time, and polymer doses on alum sludge dewatering behaviour. Waste Manag 22(7):813–819

Zhao Y, Yang Y (2010) Extending the use of dewatered alum sludge as a P-trapping material in effluent purification: study on two separate water treatment sludges. J Environ Sci Health, Part A 45:1234–1239

Zhao YQ, Keogh C, Tony A (2009) Maha, On the necessity of sludge conditioning with non-organic polymer: AOP approach. J Residuals Sci Technol 6(3):151–155

Zhao YQ, Keogh C, Tony MA (2009) On the necessity of sludge conditioning with non-organic polymer: AOP approach. J Residuals Sci Technol 6(3):151–155

Zhao XH, Zhao YQ, Kearney P (2013) Phosphorus recovery as AlPO 4 from beneficially reused aluminium sludge arising from water treatment. Environ Technol 34(2):263–268

Zhao W, Xie H, Li J, Zhang L, Zhao Y (2021) Application of alum sludge in wastewater treatment processes:“science” of reuse and reclamation pathways. Processes 9(4):612

Zhao YQ, Babatunde A, Razali M, Harty F (2008) Use of dewatered alum sludge as a substrate in reed bed treatment systems for wastewater treatment, J. Environ. Sci. Health - Part A Toxic/Hazard. Subst. Environ. Eng. 43 (1): 105–110

Zhen G, Lu X, Wang B, Zhao Y, Chai X, Niu D, Zhao T (2013) Enhanced dewatering characteristics of waste activated sludge with Fenton pretreatment: effectiveness and statistical optimization. Front Environ Sci Eng. https://doi.org/10.1007/s11783-013-0530-3

Zhou X, Jiang G, Wang Q, Yuan Z (2014) A review on sludge conditioning by sludge pre-treatment with a focus on advanced oxidation. RSC Adv 4(92):50644–50652

Zhou Xu, Jin W, Wang L, Che L, Chen C, Li S-F, Wang X-T, Renjie Tu, Han S-F, Feng X, Ren N-Q (2020a) Alum sludge conditioning with ferrous iron/peroxymonosulfate oxidation: characterization and mechanism. Korean J Chem Eng 37(4):663–669. https://doi.org/10.1007/s11814-019-0457-x

Zhou X, Jin W, Wang L, Che L, Chen C, Li S, Wang X, Tu R, Han S, Feng X, Ren N (2020b) Alum sludge conditioning with ferrous iron/peroxymonosulfate oxidation: Characterization and mechanism. Korean J Chem Eng 37(4):663–669

Acknowledgements

Waterworks plant in the southern Shibin El-Kom City, Menoufia governorate; Egypt is gratefully thanked for providing the alum sludge residual material.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

All authors designed and performed the experiments, analysis and calculations, helped shape the research and final manuscript representation.

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that there is no conflict of interest to declare.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Elsayed, Z.A., El-Sayed, I.E. & Tony, M.A. Elucidating co-conditioning strategies of aluminium-based sludge using natural biopolymeric magnetite composite for leveraging dewaterability. Appl Water Sci 14, 108 (2024). https://doi.org/10.1007/s13201-024-02167-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-024-02167-6